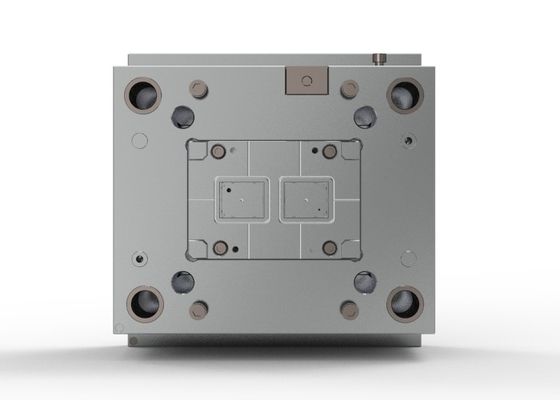

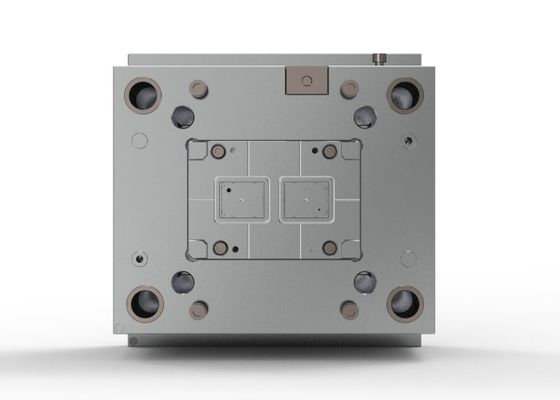

OEM / ODM : Cold Runner Injection Molding & Medical Instrument Bottom Shell (1*2) No.23672

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Armamentarium |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

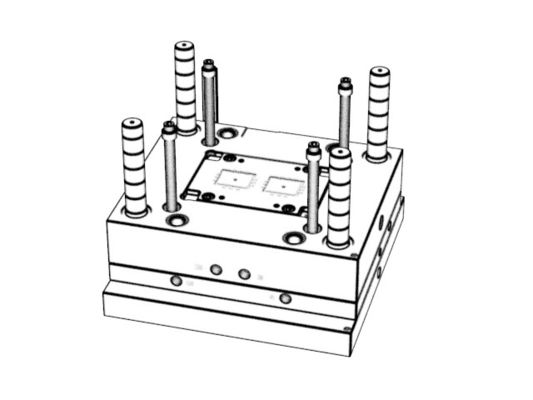

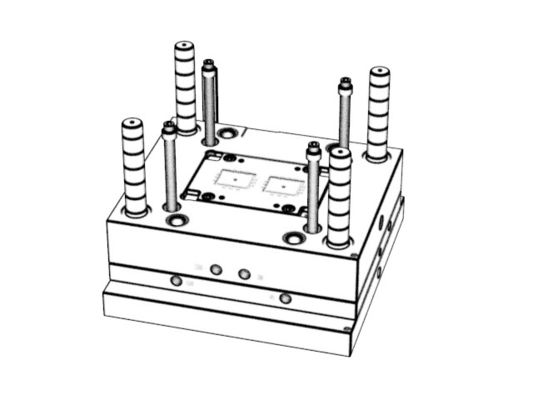

x| Size | 300.000 X 300.000 X 314.500 | IMM Tonnage | 100T |

|---|---|---|---|

| Mold Weight | 174kg | Type | Three-plates Mold |

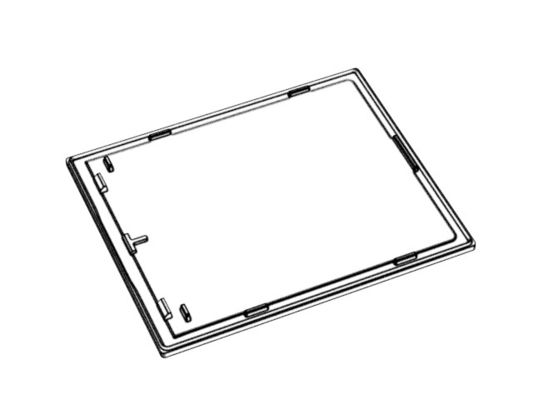

| Part Material | ENH2900 | Part Weight | 1.98g |

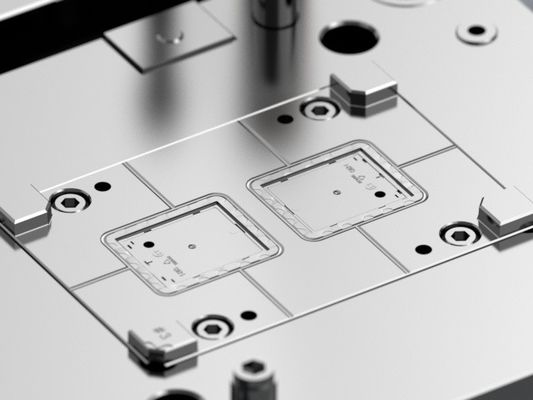

| Part Size | 42*34.38*2.3mm | Gate | Pin Point Gate |

| High Light | ENH2900 Cold Runner Injection Molding,100T Cold Runner Injection Molding,500k Shots Medical Device Molding |

||

Medical Instrument Bottom Cover (1*2)

No.23672

Part information

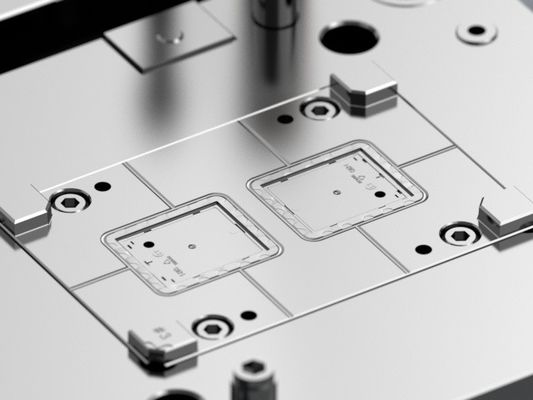

| ① Size: 300x300x314.5 ② Standard mold base P/N FCI2530.609080 ③ LKM standard |

④ Three-plates mold ⑤ Net weight: 174kg ⑥ IMM Tonnage: 100T |

||||

![]()

| Pin point gate | Cold runner | ||||

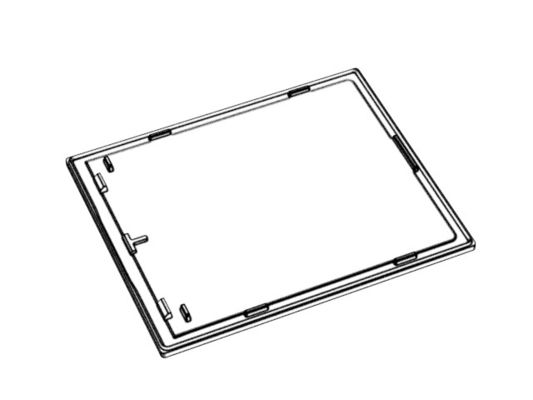

| ① Part material: ENH2900 ② Part weight: 1.98g ③ Part size: 42*34.38*2.3mm |

|||||

|

The mold is developed by Chitwing. According to the halogen-free, flame retardant and chemical resistant characteristics of part material ENH2900, the mold is designed with three plates structure and cold runner. A surface polished to SPI A2, and other surfaces EDM with VDI24#. Harden the cavity and core with 1*2/S136 so that the mold has higher hardness and better anti-wearing performance; the tool life is up to 50K shots. Molded part has smooth surface with uniform thickness. |

|||||

![]()

|

The mold is developed by Chitwing. According to the halogen-free, flame retardant and chemical resistant characteristics of part material ENH2900, the mold is designed with three plates structure and cold runner. A surface polished to SPI A2, and other surfaces EDM with VDI24#. Harden the cavity and core with 1*2/S136 so that the mold has higher hardness and better anti-wearing performance; the tool life is up to 50K shots. Molded part has smooth surface with uniform thickness. |

|||||

![]()