All Products

Contact Person :

Mr. Du

Phone Number :

+86 13302792226

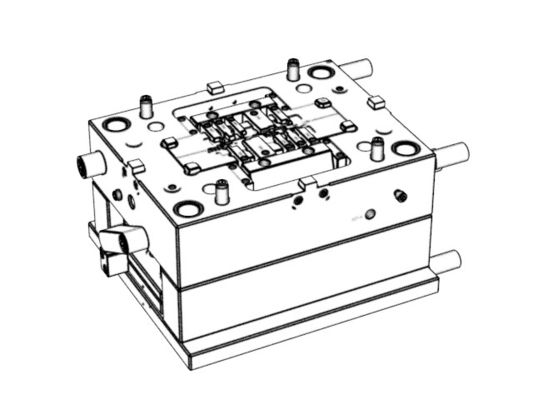

OEM / ODM : Cold Runner Injection Molding & Bracket In Glasses 1*2 No.23058-B

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Features | 5 Slides & 2 Lifters | Size | 320.000 X 350.000 X 316.000 |

|---|---|---|---|

| IMM Tonnage | 180T | Mold Weight | 222kg |

| Mold Base | FCI2735 609080 | Standard | LKM |

| Type | Three-plates Mold | Gate | Pin Point Gate |

| Part Weight | 1.5g | Injection/Runner Type | Cold Runner |

| Slide | 5 | Lifter | 2 |

| Part Material | PC | Part Size | 16.20 X 66.25 X 11.50mm |

| Highlight | plastic cold runner mould,three plates cold runner mould,polycarbonates hot runner and cold runner mold |

||

Product Description

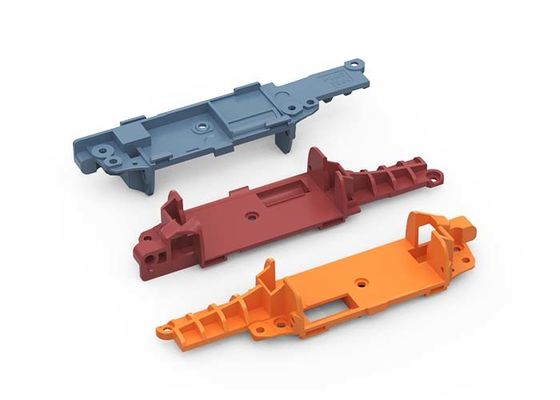

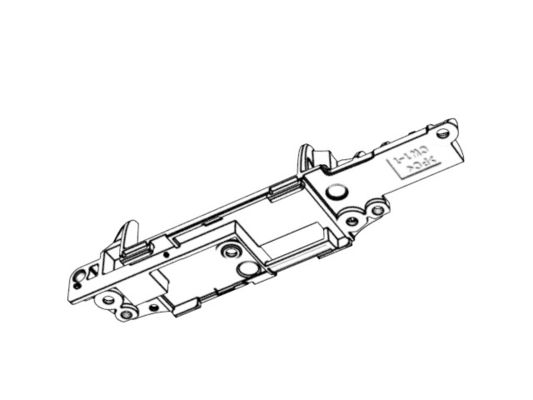

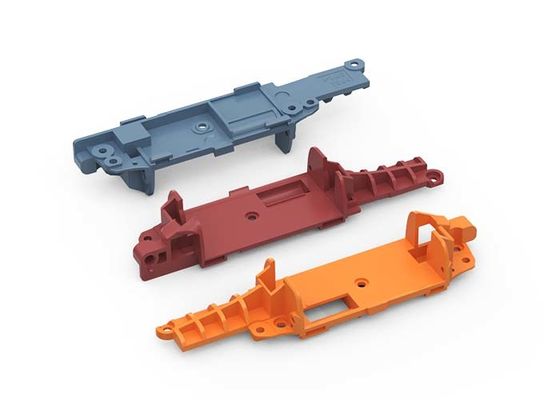

Bracket in glasses (1*2)

No.23058-B

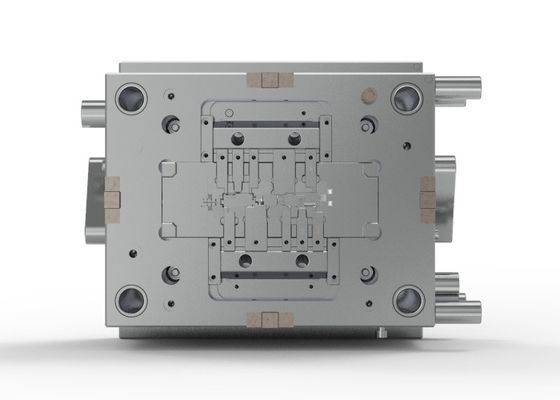

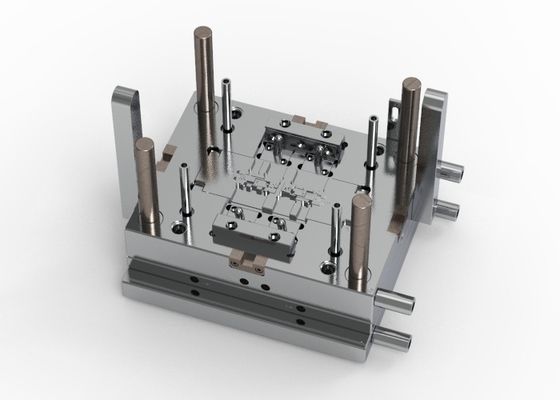

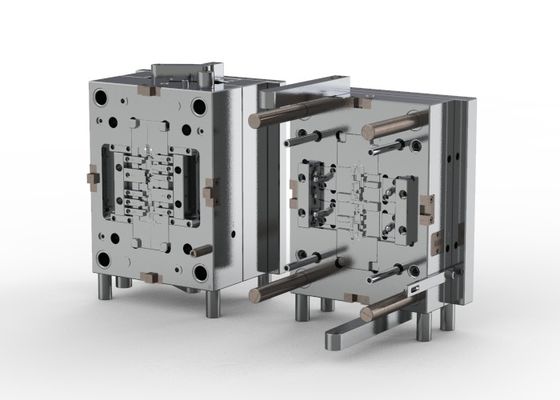

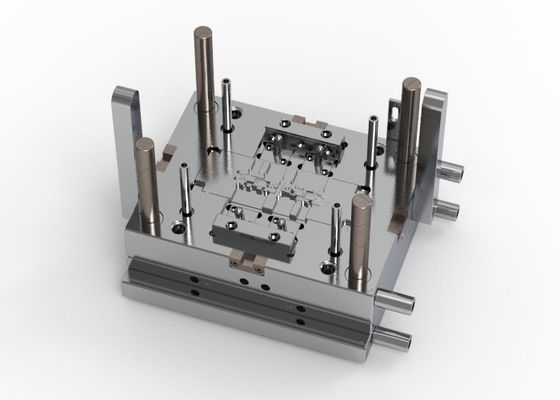

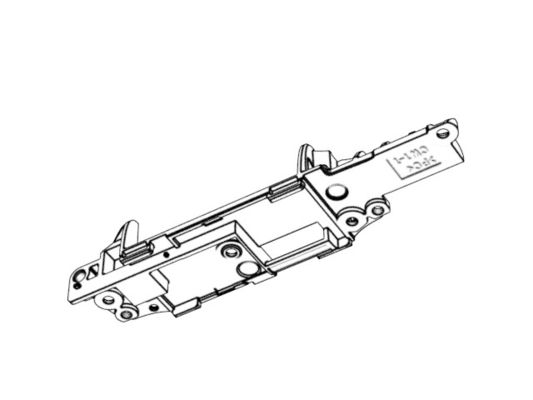

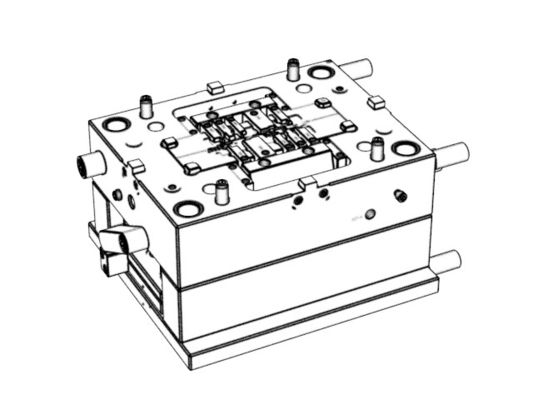

| This mold embodies sophistication as a three-plates mold, boasting a mold base of FCI2735 609080. Adhering to the esteemed LKM standard, it showcases dimensions of L 320mm x W 350mm x H 316mm. With a weight of 222kg, it demands an impressive IMM tonnage of 180T. Notably, this mold showcases 5 slides and 2 lifters, ensuring effortless demolding. Its ingenious design comprises a core, cavity, and discharge plate, accompanied by a flexible gate and self-degating mechanism, resulting in flawlessly molded parts devoid of conspicuous gate marks. |

![]()

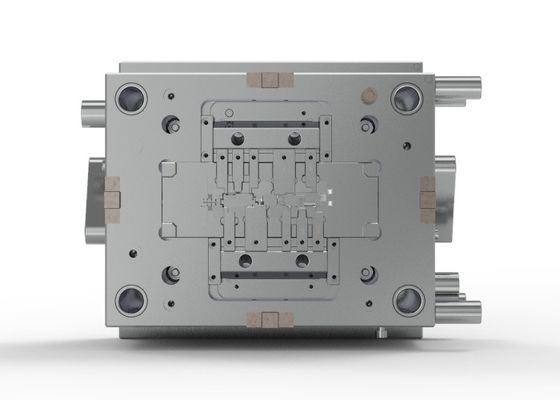

| Employing a pin point gate, this mold offers unparalleled flexibility in gate positioning. The melt utilized exhibits exceptional fluidity and withstands high temperatures, culminating in impeccably molded parts boasting remarkable clarity and a lustrous finish. The injection part material of choice is PC, while the injection part itself measures L16.2mm x W66.25mm x H11.5mm. With a weight of a mere 1.5g, this injection part exemplifies precision and finesse. |

![]()

|

The chosen injection/runner type for this mold is the esteemed Cold Runner system. To enhance its durability and resistance to wear and corrosion, the cavity and core are meticulously hardened with 1*2/S136 steel, boasting superior hardness and exceptional anti-wearing and anti-corrosion properties.

In terms of surface finish, meticulous attention has been given to ensure optimal results. One surface of the mold undergoes a meticulous VDI24 etching process, while the other surface is meticulously polished using 800# sandpaper. These meticulous surface treatments elevate the mold's surface glossiness, ultimately leading to impeccably smooth and flawless parts.

|

![]()

Display diagram

![]()

![]()

![]()

![]()

Recommended Products