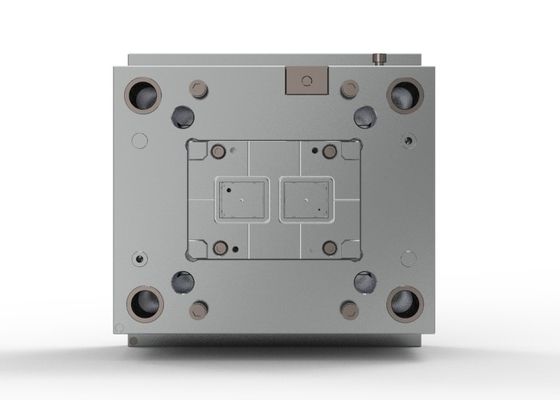

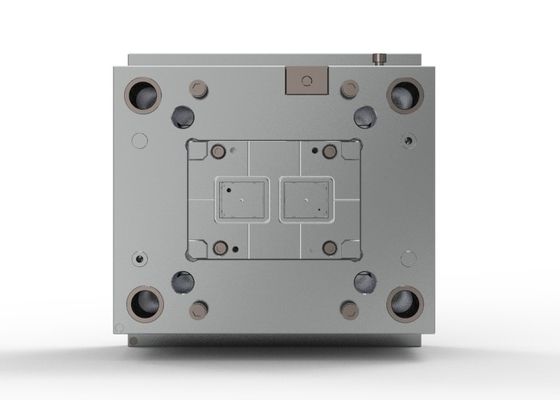

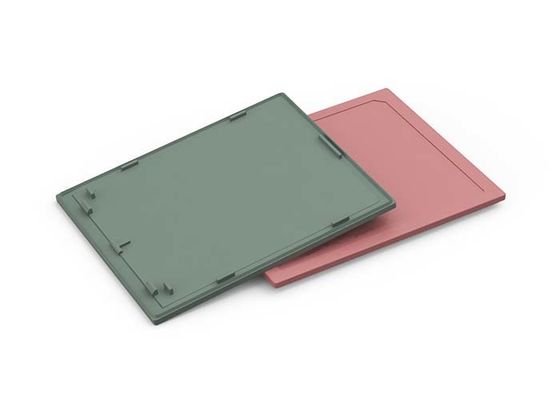

OEM / ODM : Cold Runner Injection Molding & Medical Instrument Bottom Shell (1*2) No.23672-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Armamentarium |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

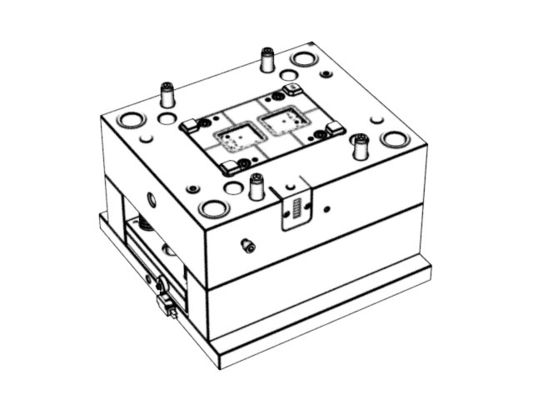

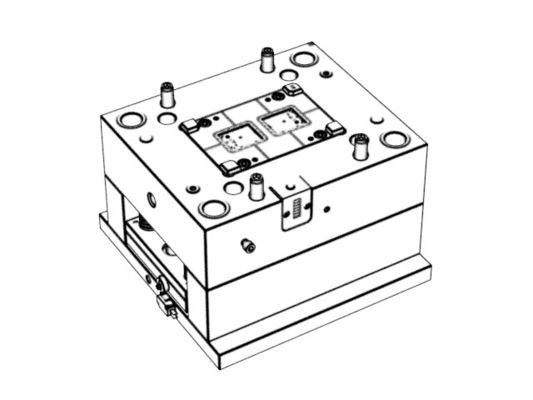

x| Size | 300.000 X 300.000 X 314.500 | IMM Tonnage | 100T |

|---|---|---|---|

| Mold Weight | 174kg | Type | Three-plates Mold |

| Part Material | ENH2900 | Part Weight | 1.98g |

| Part Size | 42*34.38*2.3mm | Gate | Pin Point Gate |

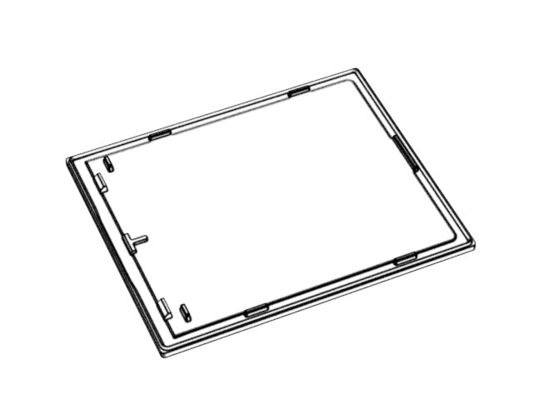

Medical Instrument Bottom Cover (1*2)

No.23672-B

Description:

| Our company specializes in the production of Cold Runner Injection Molding. Cold Runner Injection Molding is a manufacturing process used to produce plastic parts. It involves injecting molten plastic into a mold cavity through a system of channels, known as runners, which remain at ambient temperature during the injection process. The main characteristic of Cold Runner Injection Molding is that the runners are not actively cooled or heated. This means that the molten plastic in the runners solidifies and is subsequently ejected along with the part, resulting in waste material. However, Cold Runner Injection Molding offers several advantages. It is a cost-effective solution for producing large quantities of parts, as the molds are relatively simple and less expensive to manufacture. |

Application:

mobile phone accessories

battery cover

Daily necessities

Toy

Toy Accessories

Digital Accessories

Features:

| Size: | 300x300x314.5 |

| Net weight | 174kg |

| IMM Tonnage | 100T |

| mold base | Standard mold base P/N FCI2530.609080 |

| Standard | LKM |

| Type | Three-plates mold |

| Part Size | 42*34.38*2.3mm |

| Part material | ENH2900 |

| Part weight | 1.98g |

| runner | Cold runner |

| The mold has been developed by Chitwing. Taking into consideration the halogen-free, flame retardant, and chemical resistant properties of the ENH2900 part material, the mold has been designed with a three-plate structure and a cold runner system. The surface has been polished to SPI A2 standards, while the other surfaces have been subjected to Electrical Discharge Machining (EDM) using VDI24# specifications. To enhance hardness and improve anti-wear performance, the cavity and core have been hardened using 1*2/S136 material. As a result, the mold exhibits higher hardness and better resistance to wear, with a tool life of up to 50,000 shots. The molded parts produced by this mold feature a smooth surface finish and uniform thickness. |

Advantage:

| Our company specializes in the manufacturing of precision injection molds for Cold Runner Injection Molding, offering a range of distinct advantages that set us apart in the industry. Firstly, our precision molds are meticulously engineered and crafted with utmost attention to detail. This ensures the production of high-quality and consistent parts, meeting the stringent requirements of our discerning customers. Secondly, we pride ourselves on using only the finest materials in the construction of our molds. These materials are carefully selected for their exceptional durability and longevity, guaranteeing the extended lifespan of our molds. This not only reduces the need for frequent replacements but also minimizes any potential disruptions to our customers' production processes. Furthermore, our team of highly skilled engineers and technicians possesses a wealth of expertise in the field of Cold Runner Injection Molding. They are well-versed in the latest advancements and techniques, allowing them to optimize mold designs, runner systems, and cooling channels for maximum efficiency and performance. Lastly, we place great emphasis on providing exceptional customer support throughout the entire process. From initial consultations to post-production assistance, our dedicated team is committed to understanding and meeting our customers' unique requirements. We strive to foster long-term partnerships based on trust, reliability, and mutual success. |

![]()

![]()

![]()