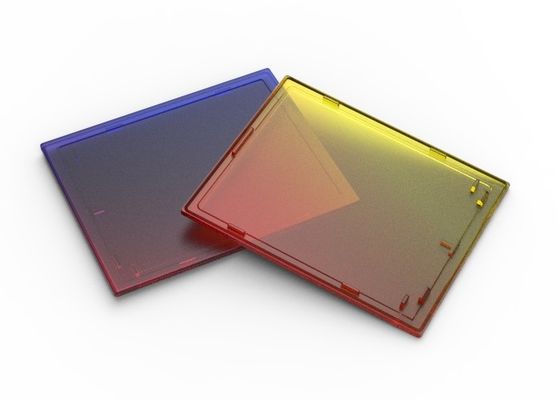

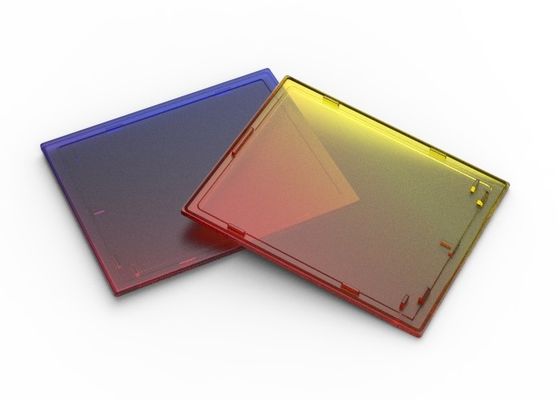

OEM / ODM : Cold Runner Injection Molding & Transparent Medical Instrument Bottom Shell (1*2) No.23672

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Armamentarium |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

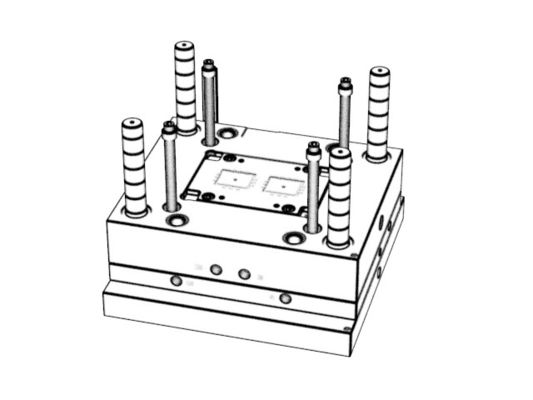

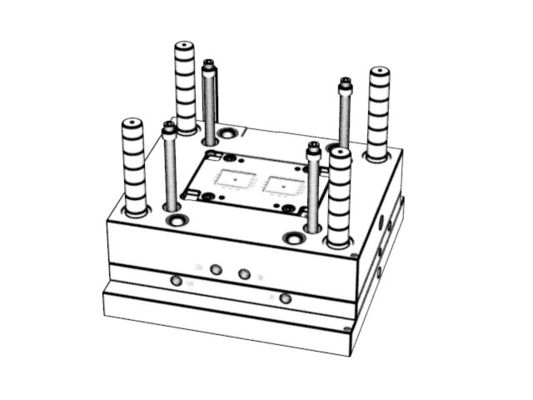

x| Size | 300 X 300 X 314.5mm | IMM Tonnage | 100(T) |

|---|---|---|---|

| Mold Weight | 174(kg) | Type | Three-plates Mold |

| Mould Base | LKM | Design Software | 3D:UG 4.0, 2D:CAD |

Transparent Medical

Instrument Bottom Cover (1*2)

No.23672

Description:

| Our company specializes in the field of Cold Runner Injection Molding, a widely used manufacturing process for producing plastic parts. This process involves injecting molten plastic into a mold cavity through a network of channels called runners. Notably, in Cold Runner Injection Molding, the runners are not actively cooled or heated, allowing them to maintain ambient temperature during the injection phase. Consequently, the molten plastic within the runners solidifies and is subsequently discarded along with the part, resulting in some waste material. Despite this drawback, Cold Runner Injection Molding offers several advantages. It is a cost-effective solution for high-volume production, as the molds required are relatively simple and less expensive to manufacture. |

Application:

mobile phone accessories

battery cover

Digital Accessories

Precision instrument accessories

Precision housing

Features:

|

The mold is meticulously designed with a cold runner, pin point gate, and three-plate structure, specifically tailored to accommodate the characteristics of ENH2900 material. This design ensures a short cycle time, improved details, optimal mold fit, minimized material loss in the runner, and more uniform pressure distribution within the cavity. With a tool life of 500,000 shots and excellent anti-wearing performance, the mold guarantees stable quality for mass production, free from leakage and burrs. Part material: ENH2900 Part weight: 1.98g Part size: 42*34.38*2.3mm |

Advantage:

| Our company specializes in precision injection mold manufacturing for Cold Runner Injection Molding, offering distinct advantages in the industry. Our precision molds are meticulously engineered and crafted to produce high-quality and consistent parts that meet stringent customer requirements. We use only the finest materials, ensuring durability and minimizing disruptions to production processes. With a team of skilled engineers and technicians, we optimize mold designs, runner systems, and cooling channels for maximum efficiency. Our exceptional customer support ensures we understand and meet unique requirements, fostering long-term partnerships based on trust and reliability. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()