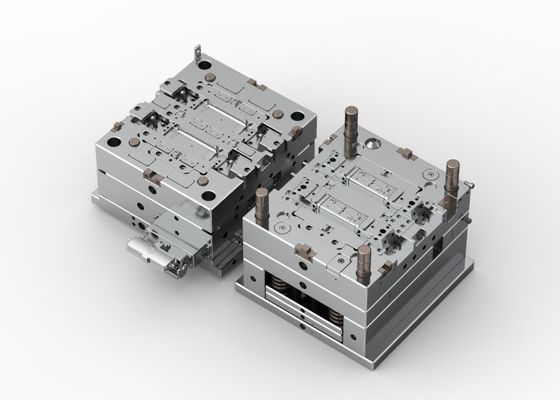

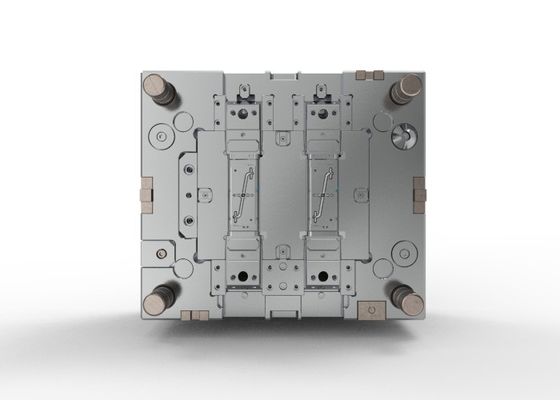

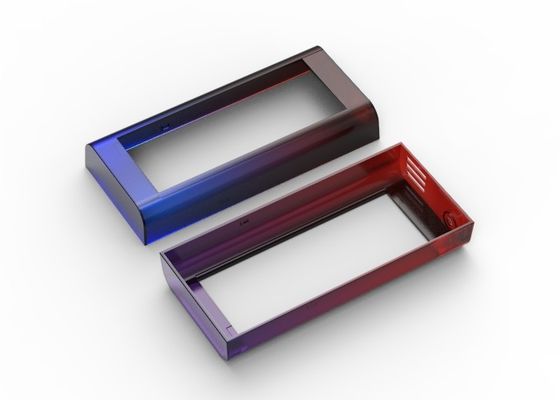

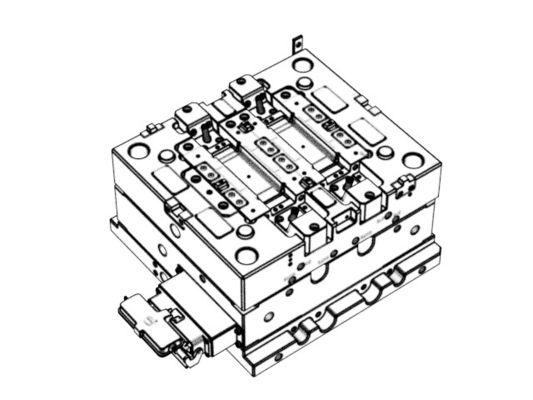

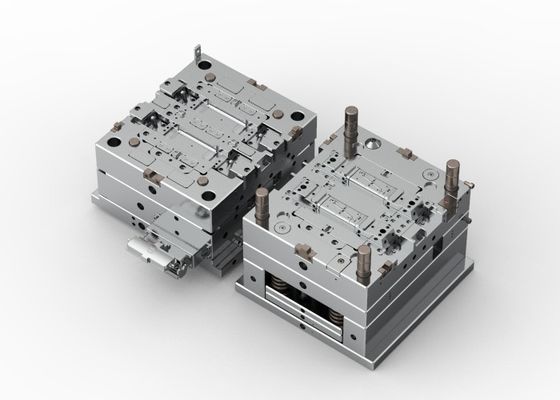

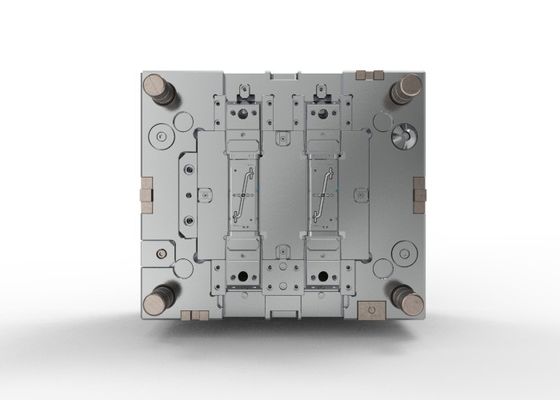

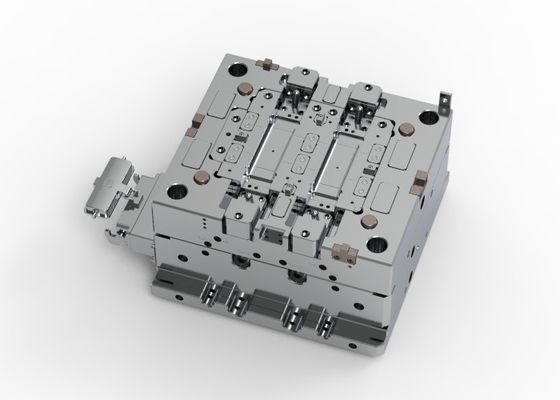

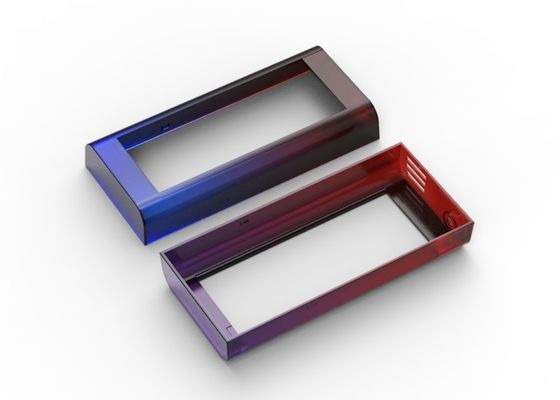

OEM / ODM : Hot Runner injection molding & Transparent Smart Doorbell Cover No.23679-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Smart Doorbell |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 180 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

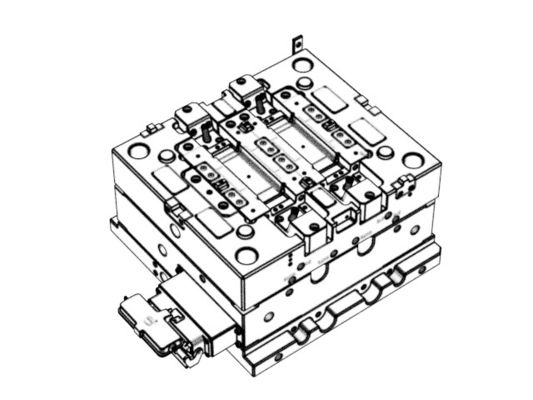

x| Size | 400 X 400 X 481 | IMM Tonnage | 110T |

|---|---|---|---|

| Mold Weight | 469KG | Design Software | <3D:UG 4.0>/ <2D:CAD> |

| Runner | Hot Runner | Mould Base | LKM |

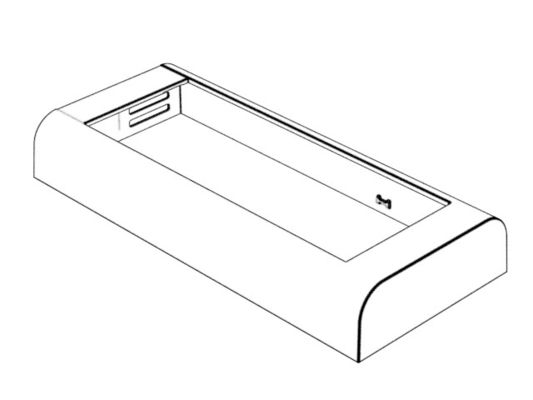

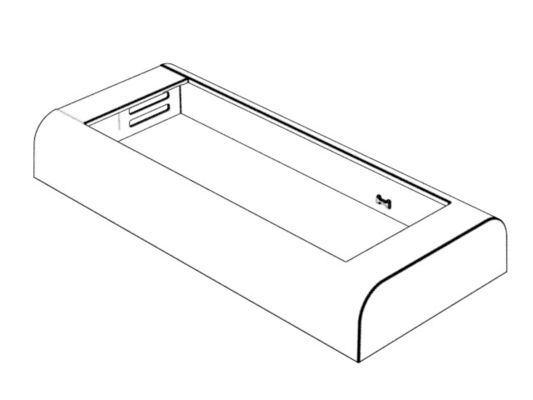

Transparent Smart Doorbell Cover (1*2)

No.23679-B

Description:

| Our company specializes in the manufacturing of hot runner injection molding molds, which are utilized in a highly efficient and precise production process for plastic parts. This process involves the utilization of a heated manifold system, known as the hot runner, to ensure a continuous flow of molten plastic into the mold cavities. One of the primary benefits of hot runner injection molding is the elimination of runners and sprues, which are typically necessary in traditional injection molding. As a result, material waste is reduced, leading to lower production costs. Moreover, hot runner systems enable faster cycle times by maintaining a consistent temperature of the molten plastic throughout the process, facilitating quicker cooling and solidification of the parts. Another notable advantage of hot runner injection molding is its capability to produce intricate and complex parts with exceptional precision. The precise control over temperature and flow of the molten plastic allows for the creation of parts with intricate geometries and tight tolerances. This makes hot runner injection molding particularly suitable for applications that demand high-quality and precise plastic parts. In conclusion, hot runner injection molding is a manufacturing process that offers significant advantages over traditional injection molding. It eliminates waste, reduces production costs, enables faster cycle times, and allows for the production of complex and precise parts. |

Application:

Electronic equipment

Smart doorbell

automotive products

medical equipment

Consumer Electronics

Home appliance

Features:

| Standard | LKM |

| Gate | Sub gate (the pin point gate turns to the side gate) |

| Tool life | 500k shots |

| Slide | 2 |

| Surface finish | |

| A surface with MT11006 etch | Other surfaces EDM with VDI21# |

| Steel of cavity | Steel of core |

| Harden (1*2/S136) | Harden (1*2/S136) |

| Mold Net Weight | 469 kg |

| Mold size | 400 X 400 X 481mm |

| Part Size | 18.94 * 18.94 * 10.45mm |

| Part net weight | 1.0g |

|

This is a three-plates mold developed by Chitwing. Harden the surface to have higher hardness and anti-wearing performance. The hot runner design minimized loss of material, saving materials and increasing the tool life. The appearance is more concise and aesthetic, with reasonable wiring and easy maintenance. |

|

Advantage:

| At our company, we specialize in the production of Hot Runner Injection Molding (Hot runner injection molding) molds that are renowned for their exceptional quality and numerous benefits. Leveraging our cutting-edge technology and extensive expertise in the field, we consistently deliver outstanding results that cater to the demands of the modern market. Advantages of our Hot runner injection molding molds: Enhanced Efficiency: Our Hot runner injection molding molds are meticulously designed to optimize production efficiency. By eliminating the need for runners and reducing cycle times, we enable faster production rates and increased output. This, in turn, leads to significant cost savings and improved productivity for our esteemed customers. Superior Quality: We recognize the paramount importance of manufacturing flawless parts. Our Hot runner injection molding molds ensure consistent and uniform heating, resulting in minimized defects such as warping, sink marks, and flow lines. This guarantees the delivery of high-quality products that adhere to the most stringent industry standards. Flexibility and Versatility: Our Hot runner injection molding molds offer unparalleled flexibility, allowing for effortless customization and adaptability to diverse production requirements. With our modular design, customers can swiftly alter mold configurations, facilitating rapid product development and reducing time-to-market. Cost-effectiveness: By eliminating the need for runners and minimizing material waste, our Hot runner injection molding molds provide substantial cost savings. Furthermore, the enhanced efficiency and superior quality of our molds contribute to reduced production costs and increased profitability for our valued customers. Reliable Performance: Our Hot runner injection molding molds are engineered to withstand the rigorous demands of high-volume production. Constructed using durable materials and precise engineering techniques, our molds ensure consistent and reliable performance, minimizing downtime and maximizing productivity. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()