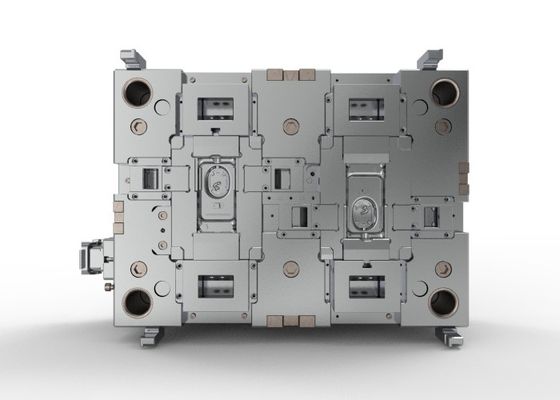

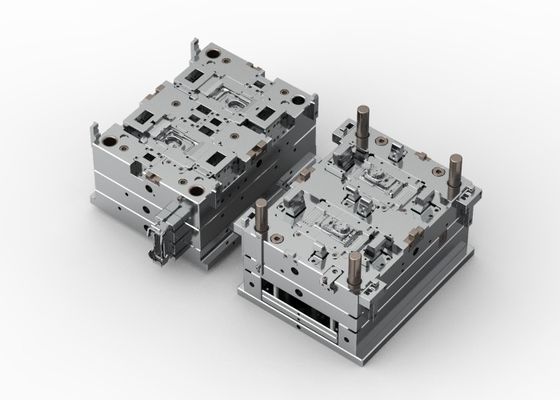

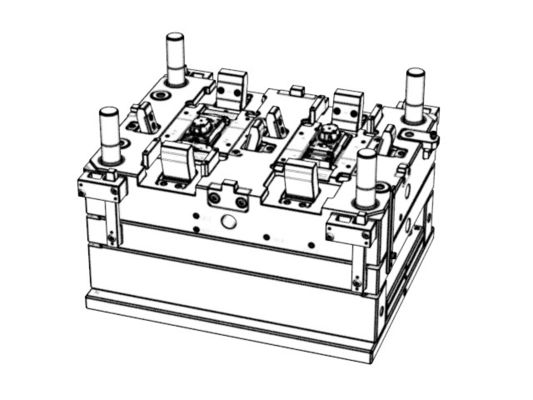

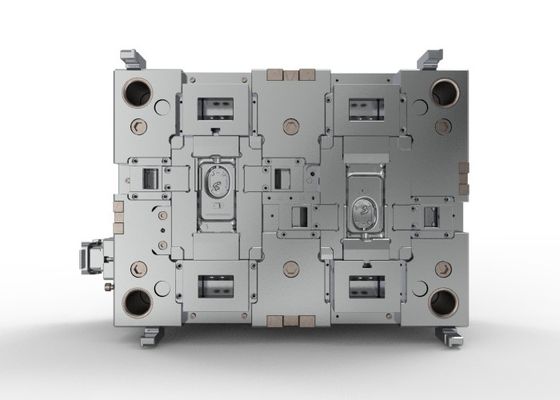

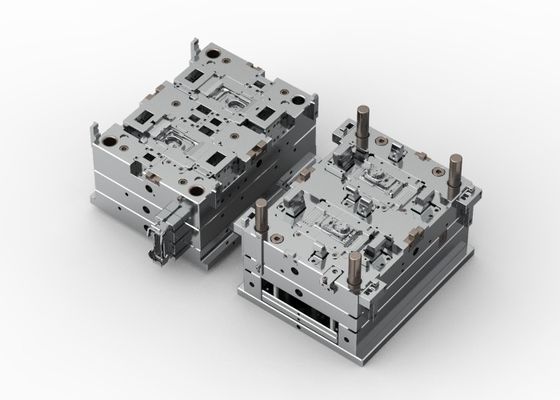

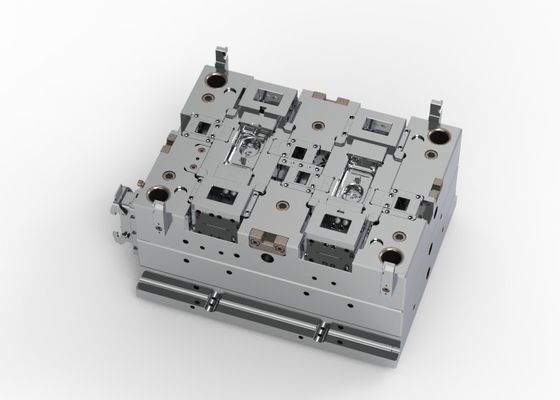

OEM / ODM : Hot Runner Injection Molding & On-board Rear Housing (1*2) No.23909-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | In-Car Products |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 180 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

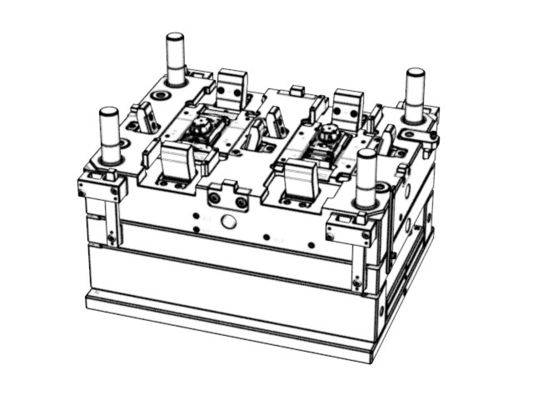

x| Size | 450.000 X 550.000 X 559.000 | IMM Tonnage | 220T |

|---|---|---|---|

| Mold Weight | 871kg | Standard | LKM |

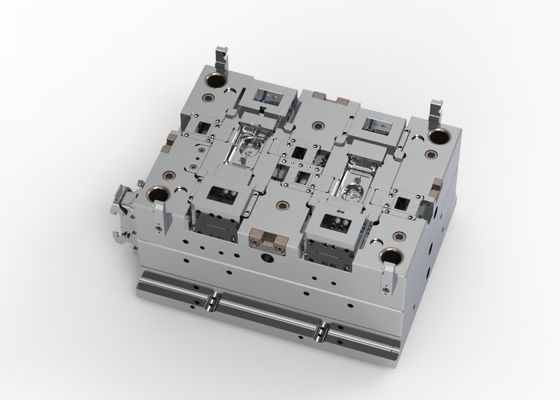

| Type | Three-plates Mold | Slide | 2 |

| Lifter | 13 | Surface Finish | VDI24#/SPI-A2 |

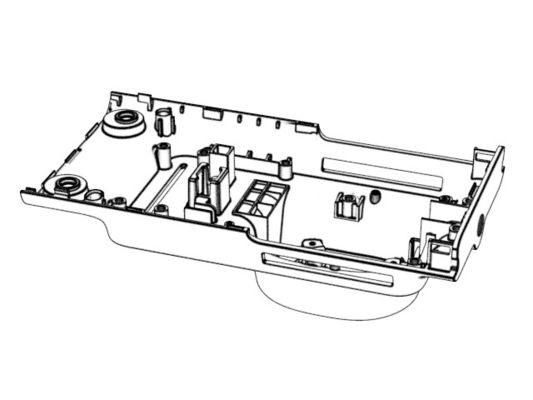

In Car Rear Housing (1*2)

No.23909-B

Description:

| Hot runner injection molding is a specialized manufacturing process used to produce plastic parts with high precision and efficiency. Unlike traditional injection molding, hot runner systems utilize heated components to maintain the molten state of the plastic material as it is injected into the mold cavity. This results in reduced cycle times, lower energy consumption, and minimized material waste. The hot runner system consists of heated manifold and nozzles, which ensure the uniform flow of the molten plastic material into the mold cavities, leading to consistent part quality and reduced production costs. Our company employs state-of-the-art hot runner technology, combined with advanced process control and monitoring, to deliver superior quality plastic parts to our clients across various industries. |

Application:

digital shell

mobile phone accessories

Mouse and keyboard

Daily necessities

Precision accessories

Features:

| Mold base P/N | DI4055 110100100 |

| Standard | LKM |

| Mold Size | Length:450 Width:550 Height:559 |

| Slide | 4 |

| Lifter | 13 |

| Mold net weight | 871kg |

| IMM Tonnage | 220T |

| Surface finish | ① A surface laser with VDI24# |

| ② A surface EDM with SPI-A2 | |

| Part outter surface polished, low glossiness and free of sand paper mark, and touch-friendly. | |

| Steel of cavity & core | Harden (1*2/S136) |

|

Harden steel for cavity and core, good hardness, anti-wearing, anti-corrosion, mass production tool life 500k shots. |

|

| This tooling with hot sprue + 3 plates pin point gate + side gate. Easy for tool build and W/O cold sprue (cost effective by saving material) |

|

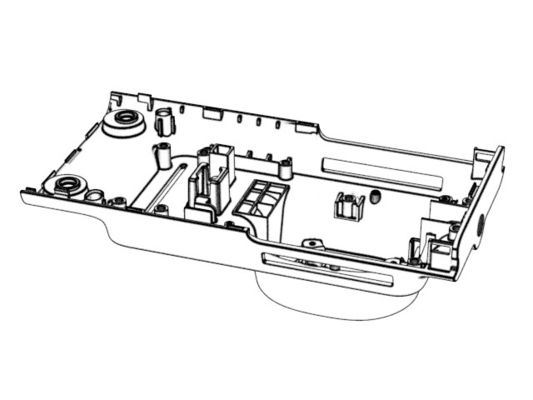

| Overall size | Length 115.95 |

| Width 60.93 | |

| Height 37.15 | |

| Net weight | 19.95g |

| Part size | 115.95x60.93x37.15mm |

Advantage:

| Hot runner injection molding is a cornerstone of our company's manufacturing capabilities, offering a multitude of advantages in the production of plastic parts. By leveraging hot runner technology, we are able to significantly reduce material waste, enhance part quality, and improve production efficiency. Our expertise in utilizing hot runner systems allows us to mold intricate part geometries, providing our clients with innovative design possibilities. Through the utilization of hot runner injection molding, we demonstrate our commitment to delivering high-quality, cost-effective, and environmentally conscious plastic manufacturing solutions. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()