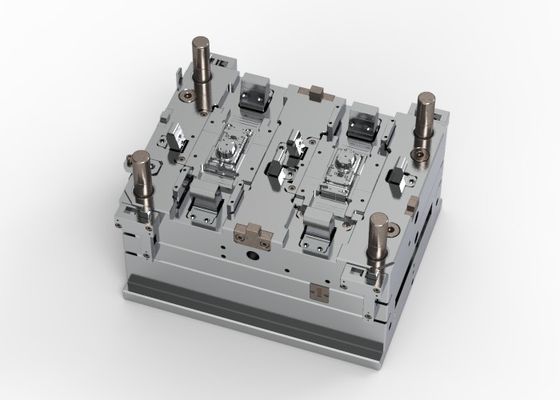

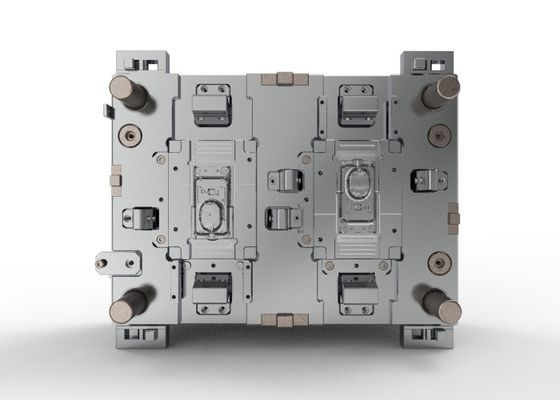

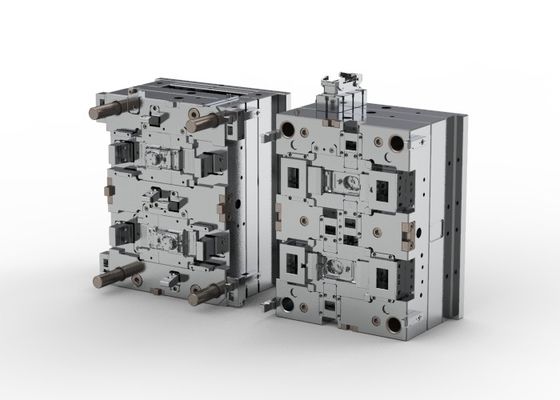

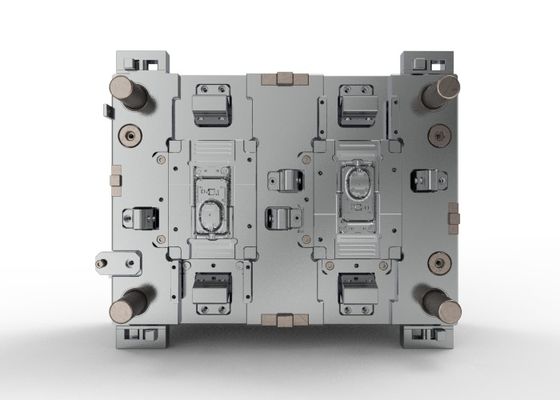

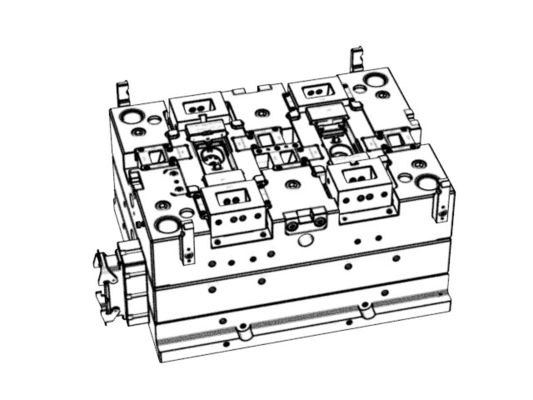

OEM / ODM : Hot Runner Injection Molding & Transparent On-board Rear Housing (1*2) No.23909-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | In-Car Products |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 180 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

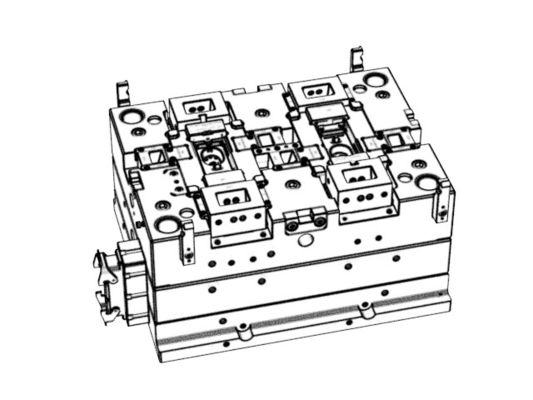

x| Size | 450.000 X 550.000 X 559.000 | IMM Tonnage | 220T |

|---|---|---|---|

| Mold Weight | 871kg | Steel Of Cavity & Core | 1*2/S136 |

| Slide & Lifter | 4/13 | Standard | LKM |

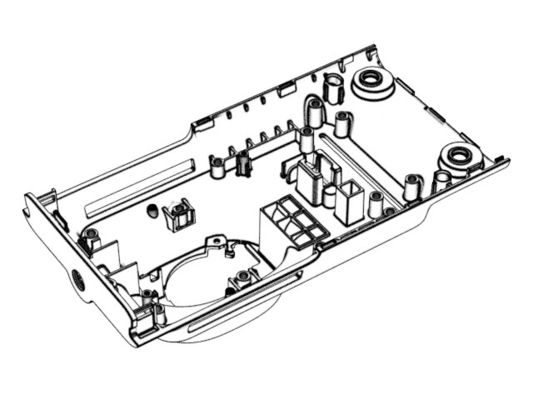

Transparent On-board Rear Housing (1*2)

No.23909-B

Description:

| Hot runner injection molding is a highly efficient and precise manufacturing process used to produce plastic parts with minimal waste and high consistency. This method involves the use of a heated manifold system to deliver molten plastic material to the mold cavities. The hot runner system ensures that the plastic remains in a molten state as it is injected into the mold, resulting in faster cycle times and reduced material waste compared to traditional cold runner systems. The precise control of temperature and flow within the hot runner system allows for the production of complex and high-quality plastic parts with minimal gate marks and sprue waste. This advanced molding technique is widely utilized in industries such as automotive, electronics, and medical devices for its ability to produce intricate parts with superior quality and efficiency. |

Application:

phone case

digital product

precision instrument

medical equipment

Features:

| Mold base P/N | DI4055110100100 |

| Mold net weight | 871kg |

| IMM Tonnage | 220T |

| Mold Length | 450 |

| Mold Width | 550 |

| Mold Height | 559 |

| Standard | LKM |

| Slide | 2 |

| Lifter | 13 |

| Type | Three-plates mold |

| Gate | Side gate |

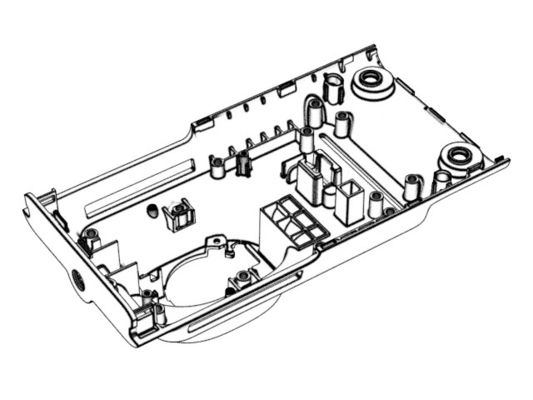

| Part material | PC |

| Injection/runner type | Hot runner |

| Surface finish | ① A surface laser with VDI24# ② A surface EDM with SPI-A2 |

| Steel of cavity & core |

Harden (1*2/S136) Long tool life(500k shots) with harden cavity/core block, with good hardness, strength, anit- wearing,anti-corrosion. |

| Part size | 115.95*60.93*37.15 |

| Part Net weight | 19.95g |

|

cost effective with cold sprue free runner (hot spure to 3 plates cold runnner, without cold spure) |

|

Advantage:

| Hot runner injection molding stands as a testament to our company's commitment to advanced manufacturing techniques. By harnessing the capabilities of hot runner technology, we are able to minimize material waste, elevate product quality, and streamline production processes. Our proficiency in hot runner systems enables us to craft intricate part designs, offering our clients a spectrum of innovative possibilities. Through the adoption of hot runner injection molding, we showcase our dedication to delivering sustainable, high-quality plastic manufacturing solutions. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()