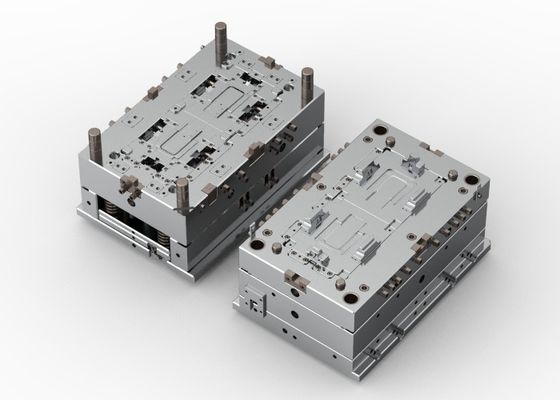

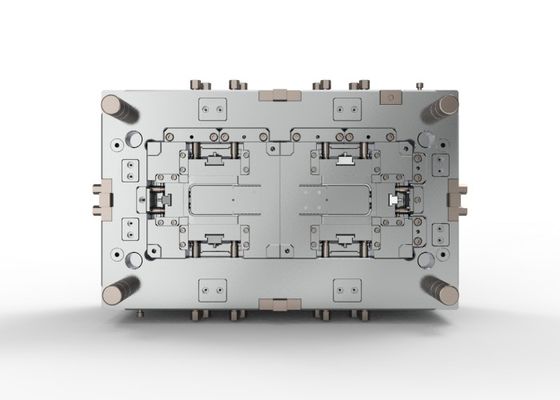

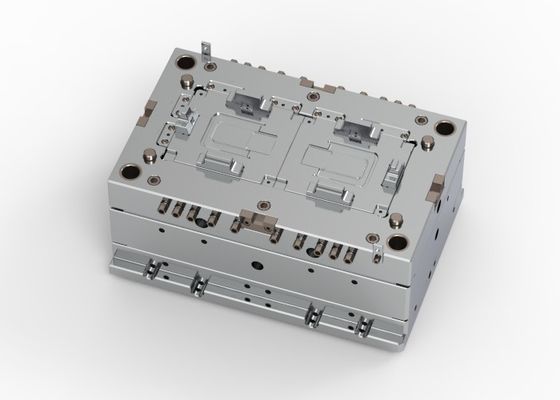

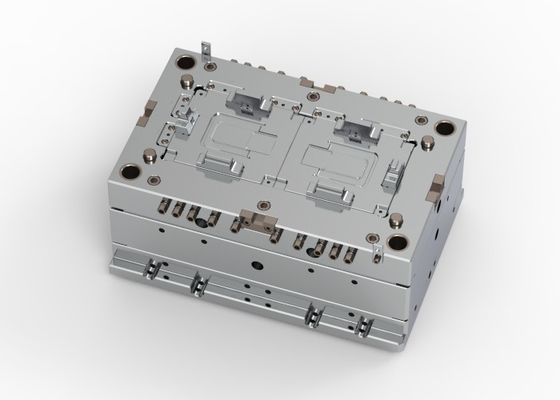

OEM / ODM : Hot Runner Injection Molding & On-board Foot Rest (1*2) No.23914-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | In-Car Products |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 180 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

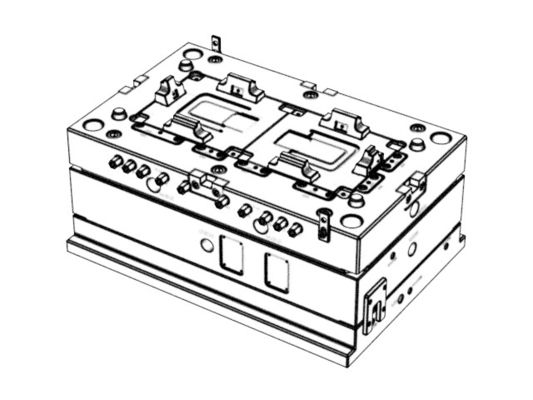

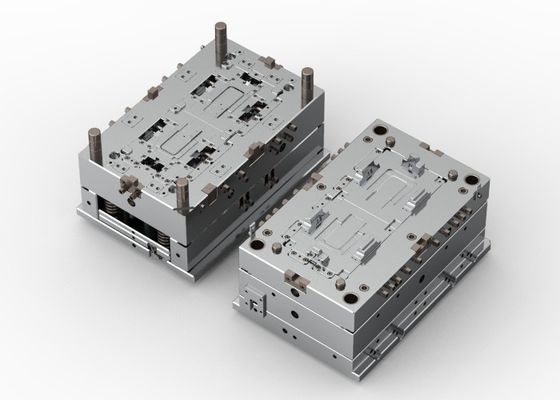

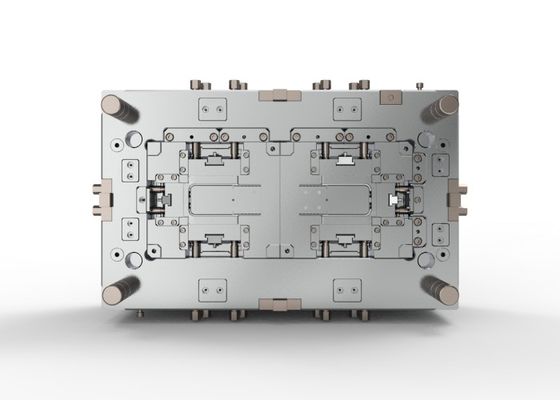

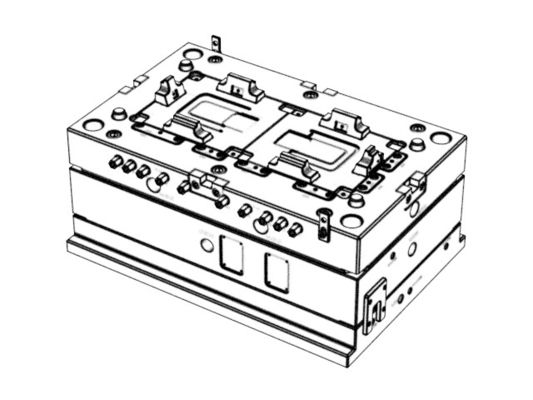

x| Size | 450.000 X 650.000 X 548 | IMM Tonnage | 130T |

|---|---|---|---|

| Mold Weight | 1075kg | Slide | 3 |

| Lifter | 3 | Type | Two-plates Mold |

| Standard | LKM | Gate | Spure Gate |

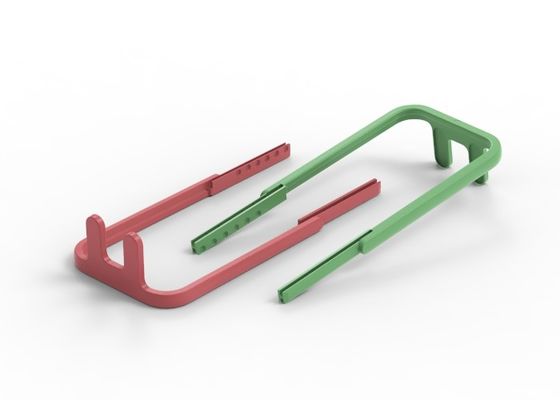

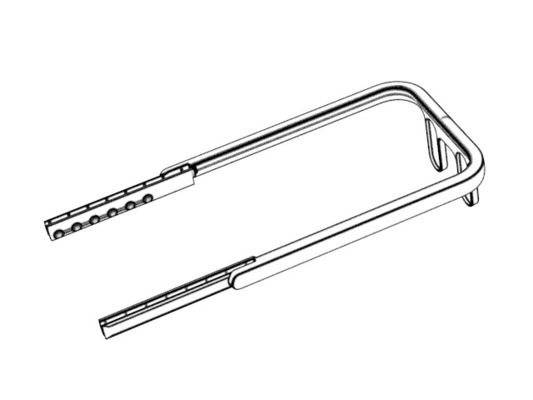

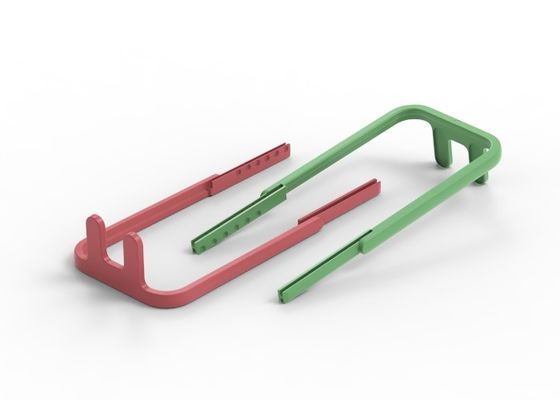

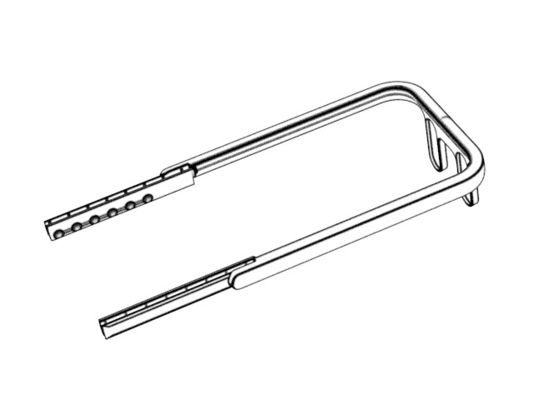

On-board Foot Rest (1*2)

No.23914-B

Description:

| we employ hot runner injection molding technology. This advanced method uses a heated runner system to deliver molten plastic resin into the mold cavities, producing high-quality plastic parts. Compared to traditional cold runner injection molding, hot runner injection molding reduces material waste, improves production efficiency, and ensures part consistency and precision. By precisely controlling the temperature and flow of the molten plastic, we are able to produce aesthetically pleasing, dimensionally accurate plastic parts that meet our customers' demand for high-quality products. |

Application:

mobile phone holder pendant

digital product

mobile phone accessories

shell

plastic products

Features:

| Mold base P/N | CI4065A85B130C110 |

| Standard | LKM |

| Length Width Height | 450x650x548 |

| Net weight | 1075kg |

| Type | Two-plates mold |

| Injection/runner type | Hot runner |

| Slide | 3 |

| Lifter | 3 |

| IMM Tonnage | 130T |

| Part material | PA+50% GF |

| Part size | 61.00 X 130.95 X 28.34mm, weight 7.75g |

| Gate | Spure gate |

|

This mold with ①A surface EDM to Charmilles VDI24# ② Internal surface polished to SPI-B1, so that the mold surface has a good glossiness, roughness and slight sandpaper marks. the molded part has a skin-friendly surface. The cavity and core are harden (1*2/S136) with high hardness, anit-corrosion, anti-wearing. long tool life. |

|

Advantage:

| Our company's hot runner injection molding molds offer several distinct advantages. Firstly, they enable the production of complex and intricate plastic parts with high precision and consistency. The use of hot runner systems allows for the efficient and uniform flow of molten plastic material, resulting in reduced material waste and improved production efficiency. Additionally, these molds facilitate faster cycle times, leading to increased productivity and cost-effectiveness. The ability to precisely control the temperature and flow of the molten plastic also ensures superior part quality and aesthetics. Overall, our hot runner injection molding molds provide a competitive edge in producing high-quality plastic components for various industries. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()