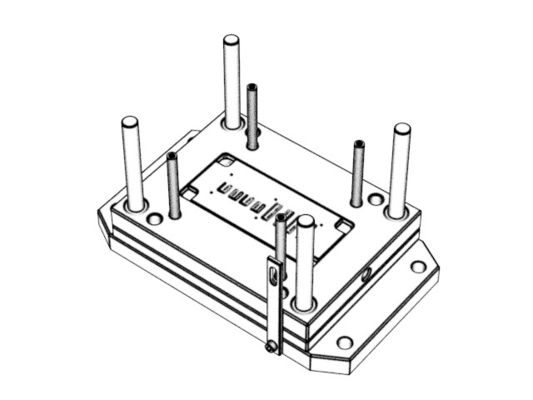

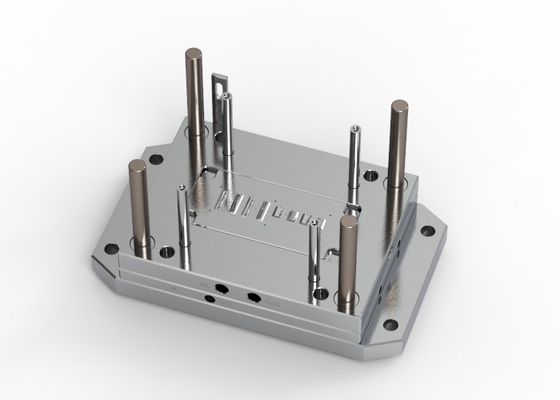

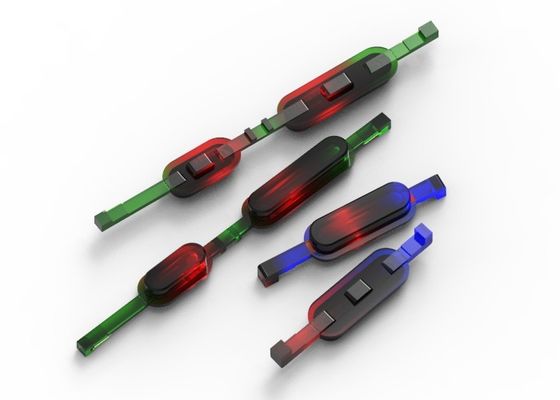

OEM / ODM : Cold Runner Injection Molding & Transparent Scan Pen Power Key (4+4) No.24006&24007-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Scanning Pen |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

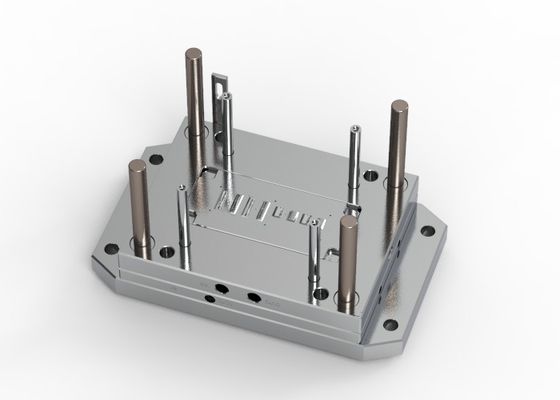

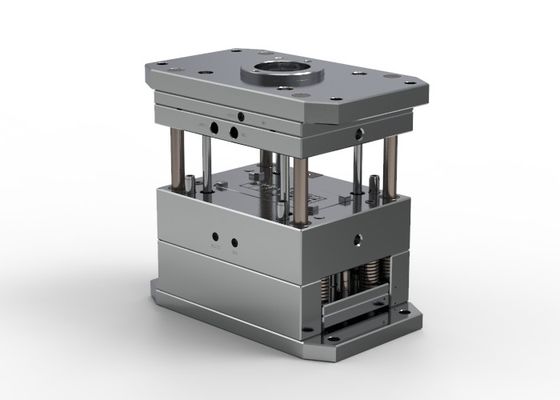

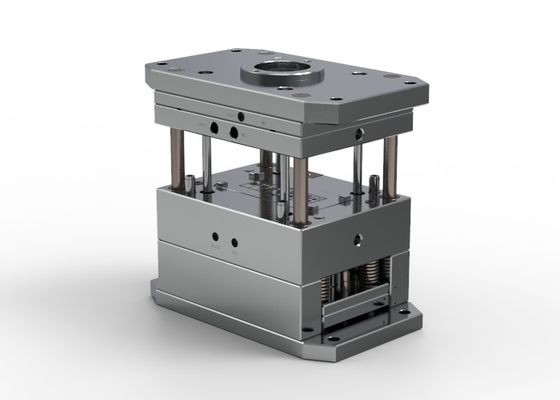

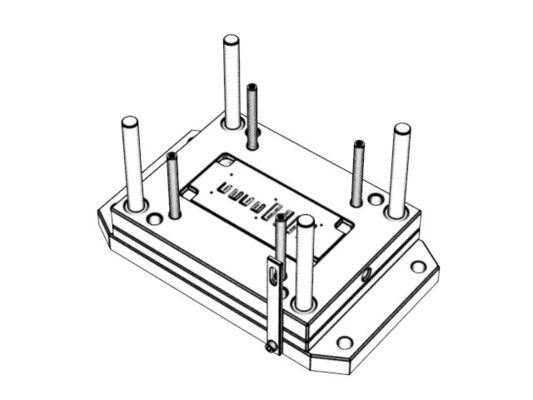

x| IMM Tonnage | 200T | Size | 230 X 390 X 266 |

|---|---|---|---|

| Mold Weight | 181KG | Brand | Chitwing |

| Place Of Origin | China | Mold Base P/N | Custom FCI2330.308080 |

| Type | Three-plates Mold | ||

| High Light | Transparent key Cold Runner Injection Molding,Power Key Cold Runner Injection Molding |

||

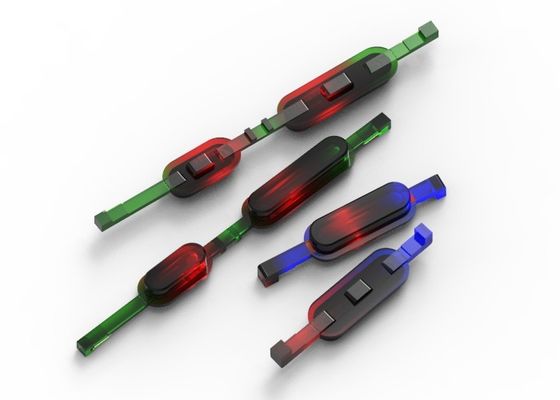

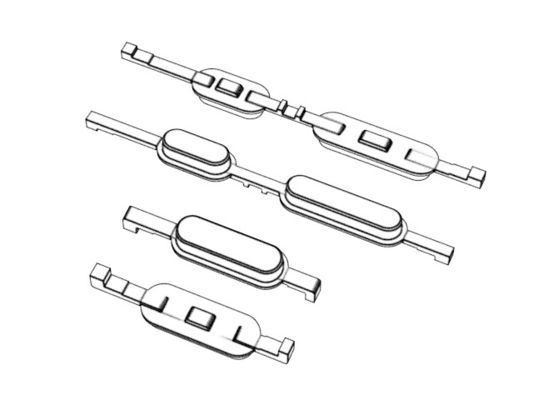

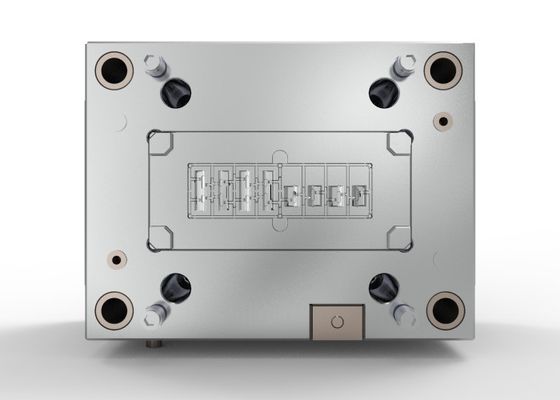

Transparent Scan Pen Power Key (4+4)

No.24006&24007-B

Description:

| Cold runner injection molding is a cutting-edge manufacturing process used to create plastic parts with precision and efficiency. This method involves injecting molten plastic into a mold through a network of channels known as the cold runner. The design of the cold runner system is crucial in maintaining the plastic material at an optimal temperature to prevent premature solidification. Once the mold cavity is filled and the material solidifies, the resulting part is ejected, while the excess material in the cold runner is recycled for future use. This approach is highly sought after for its ability to minimize material waste and reduce production costs, making it an ideal choice for high-volume production runs. |

Application:

Precision keys

electronic doorbell

Consumer Electronics

mobile phone accessories

Peripheral accessories

Features:

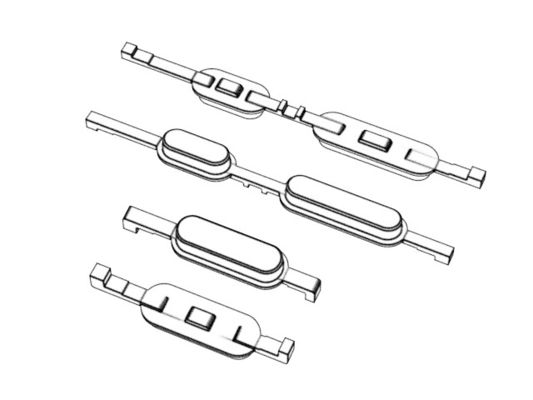

| Double-shot molding | ||

| The mold net weight | 181kg | |

| Mold size | Length | 230 |

| Width | 390 | |

| Height | 266 | |

| IMM tonnage | 200T | |

| Brand | Chitwing | |

| Custom mold base P/N | FCI2330.308080 | |

| Injection/Runner Type | Cold Runner | |

| Gate | Side gate | |

|

The pin point gate turns to the side gate. The sprue bushing does not need to be off center of mold base. |

||

| Type | Three-plates mold | |

| Standard | LKM | |

| Part material | PC+ABS / PC+TPU | |

| Part size | 1st shot: 11.20*3.80*2.34 | |

| 2nd shot: 31.85*2.05*1.09 | ||

| Part weight | 1st shot: 0.2g | |

| 2nd shot:0.1g | ||

| Surface finish | A surface polishing to SPI-A1 | |

| Steel of cavity | Harden (4+4/S136) | |

| Steel of core | Harden (4+4/S136) | |

|

This is a custom moldbase 2k mold. Cavity & core well harden and high polished with high harness and anti-wearing performance. Meet mass production requirement and with 500k shots tool life. |

||

Advantage:

| Our company's Cold Runner Injection Molding molds offer a multitude of advantages in the manufacturing process. Firstly, our molds are engineered to deliver precise and consistent part production, resulting in minimal material wastage and superior product quality. The robust construction of our molds ensures longevity and reliability, leading to cost savings and sustained productivity. Furthermore, our molds are designed to optimize cooling and cycle times, thereby increasing production efficiency and reducing lead times. Additionally, the versatility of our molds allows for customization to accommodate a wide range of part geometries and material specifications, catering to diverse production needs. |

![]()

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()

![]()

![]()