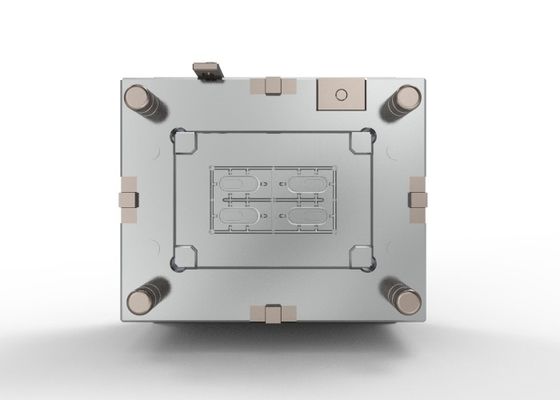

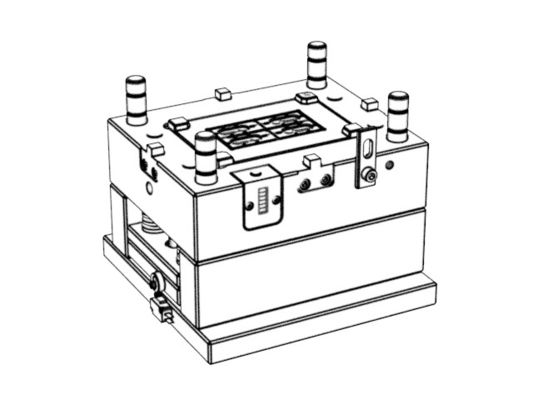

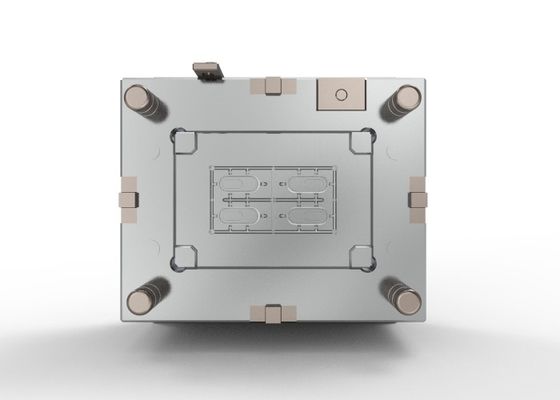

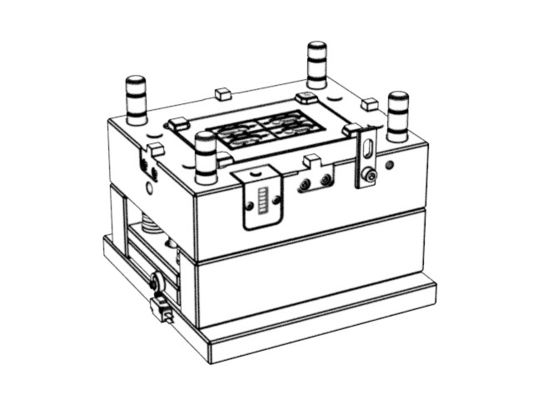

OEM / ODM Injection Molding Scan Pen Camera Trim Ring (1*4) No.24005-D

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Scanning Pen |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Size | 250 X 250 X 241 | IMM Tonnage | 110T |

|---|---|---|---|

| Mold Weight | 88KG | Part Weight | 0.2g |

| Part Material | POM | Mold Base | Standard FCI2530.509080. |

| Runner | Cold Runner | Mould Life | ≥500000 Shots |

| Design Software | 3D:UG 4.0, 2D:CAD | ||

| High Light | Camera Trim Ring Injection Molding,Scan Pen Injection Molding |

||

Scan Pen Camera Trim Ring (1*4)

No.24005-D

Description:

| Cold runner injection molding provides numerous advantages compared to other molding methods. It helps in minimizing material wastage by allowing the reuse of the runner system for subsequent molding cycles, leading to cost savings and enhanced efficiency. Moreover, the utilization of a cold runner system offers better control over the molding process, resulting in improved part quality and consistency, which is especially beneficial for high-precision molding applications requiring tight tolerances. Additionally, the cold runner design facilitates easier color changes and material transitions, making it a versatile option for manufacturers with diverse production needs. In conclusion, Cold Runner Injection Molding is known for its cost-effectiveness, precision, and flexibility, making it a preferred choice for various industrial applications. |

Application:

Smart doorbell

Consumer Electronics

plastic casing

plastic component.

Features:

| Mold base | Standard FCI2530.509080. |

| Mold size | 250 X 250 X 241mm |

| Net weight | 88kg |

| Tool life | 500K shots |

| Features | Make a plating bracke |

| Fit 110T machine | |

|

The material of the part is POM, with dimensions of 33.65 * 2.26 * 14.52mm, and a net weight of merely 0.2g. |

|

|

This three-plate mold is created following LKM standards, featuring a pin point gate that can be converted into a side gate. The sprue bushing is positioned at the center of the mold base. The resulting molded part boasts consistent high quality and does not require any additional post-processing, leading to significant reductions in labor costs. The surface is polished using 600# sandpaper, while the secondary surface undergoes EDM with Charmilles VDI21#, resulting in a smooth cavity surface. Both the cavity and core are hardened using 1*4/S136 to achieve increased hardness and anti-wear performance. The smooth runner and stable cavity pressure guarantee that the molded part has a flawless surface with clear details and no burrs. |

|

Advantage:

| Our Cold Runner Injection Molding technology provides numerous benefits that set it apart as a top choice in the industry. To start, these molds are engineered to reduce material waste, resulting in both cost savings and environmental advantages. The cold runner system enhances reusability, promoting cost-effectiveness. Furthermore, the precise control offered by this system ensures consistent part quality, making it perfect for high-precision tasks. In addition, the cold runner design's flexibility allows for easy color changes and material transitions, meeting a wide range of production requirements. In summary, our Cold Runner Injection Molding process is known for its efficiency, accuracy, and versatility, making it an excellent solution for various industrial needs. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()