All Products

Contact Person :

Mr. Du

Phone Number :

+86 13302792226

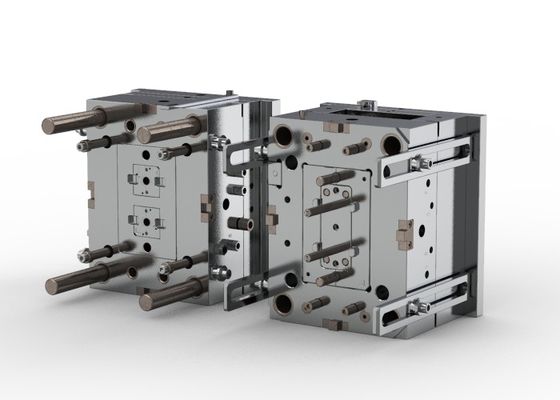

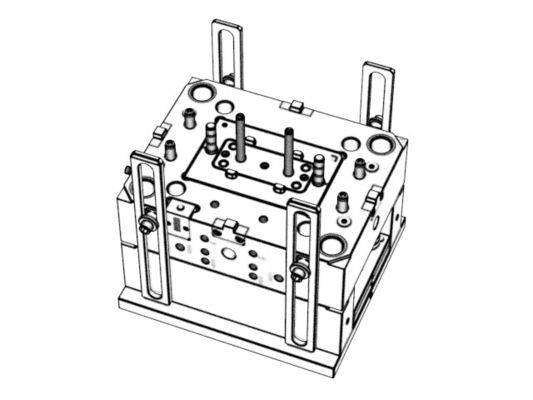

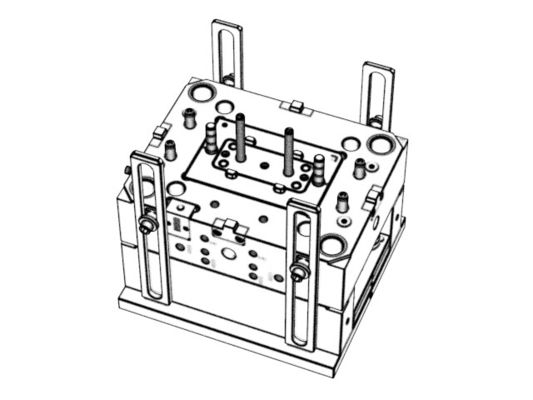

Transparent Battery Case (1*2) / Cold runner / Three-plates mold No.24500

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | E -cigarettes |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Features | Push Plate | Size | 320 X 350 X 426 |

|---|---|---|---|

| IMM Tonnage | 110 T | Mold Weight | 294KG |

| Part Material | PC+ABS | Type | Three-plates Mold |

| Gate | Tab Gate (the Pin Point Gate Turns To The Side Gate) | Custom Mold Base P/N | FCI3527.110100105 |

| Mold Runner | Hot Sprue Cold Runner | ||

| High Light | Battery Housing Precision Injection Molding,Three Plate Precision Injection Molding,LKM Injection Molding Cold Runner |

||

Product Description

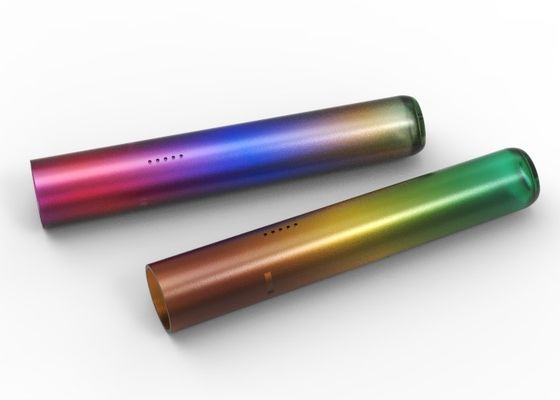

Transparent

Battery Housing (1*2)

No.24500

| Chitwing | Mold base: custom mold base FCI3527.110100105 | Mold weight | |||||

| Length | 320 | Width | 350 | Height | 426 | 294kg | |

| LKM standard | Three-plates mold | Cold runner | IMM Tonnage | ||||

| 110T | |||||||

![]()

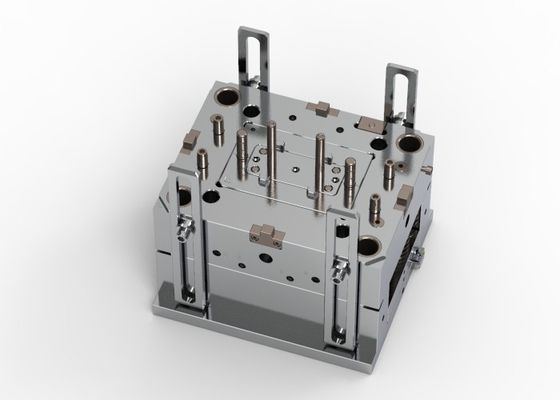

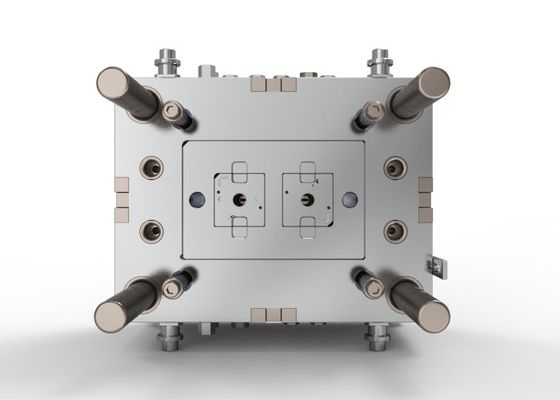

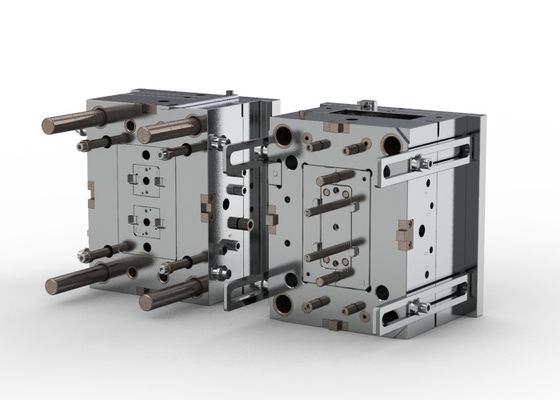

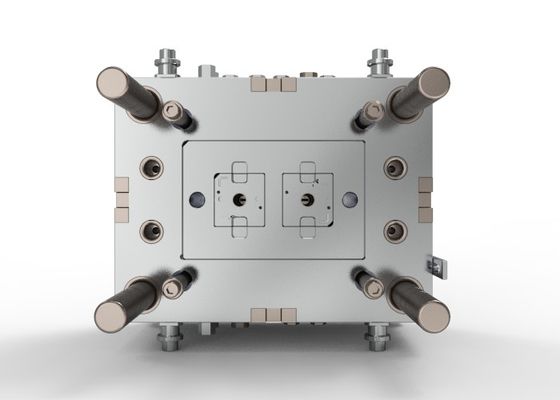

| The mold is designed with mold base > HB280, tab gate, and the pin point gate turns to the side gate to ensure the melt flow. | |||||||

![]()

| The mold surface polished to 1000# sandpaper to increase the surface glossiness, so that the molded part is smoother w/o sticking with the mold; harden the cavity and core with 1*2/S136 to improve the hardness (> HRC50) and anti-wearing performance, meeting the requirements for mass production; tool life up to 500k shots. The push plate structure provides uniform thrust and smooth demolding, preventing molded parts from deforming | |||||||

![]()

|

|

||||||||||

☆ Features:Push plate

![]()

Display diagram

![]()

![]()

![]()

![]()

| The mold is designed with mold base > HB280, tab gate, and the pin point gate turns to the side gate to ensure the melt flow. The mold surface polished to 1000# sandpaper to increase the surface glossiness, so that the molded part is smoother w/o sticking with the mold; harden the cavity and core with 1*2/S136 to improve the hardness (> HRC50) and anti-wearing performance, meeting the requirements for mass production; tool life up to 500k shots. The push plate structure provides uniform thrust and smooth demolding, preventing molded parts from deforming | |||||||

Recommended Products