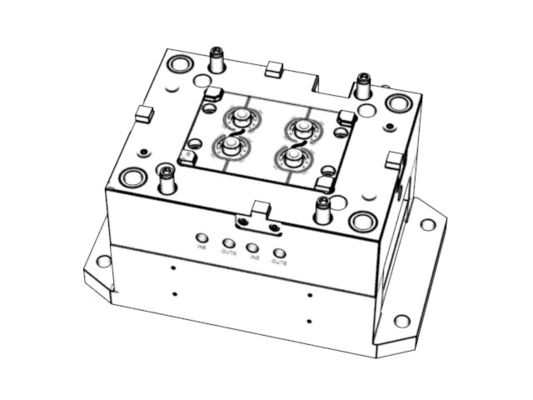

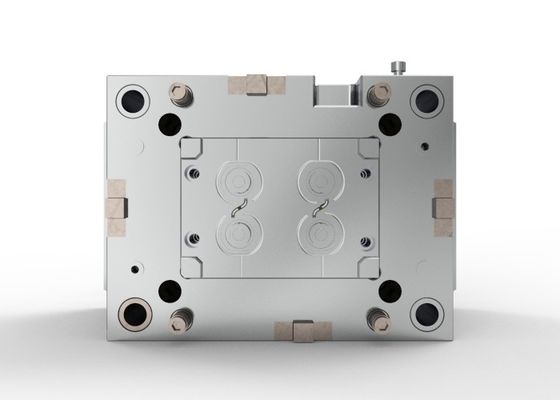

OEM / ODM : Double Injection Molding & Smart Doorbell Button (1*4) No.23675 & 23676-B

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Smart Doorbell |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

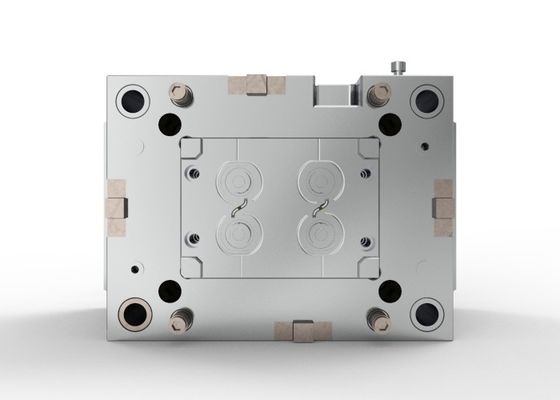

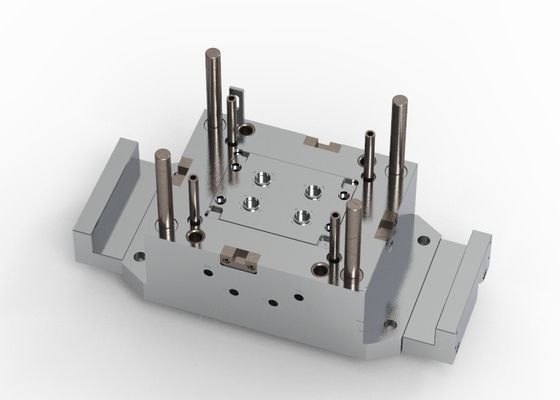

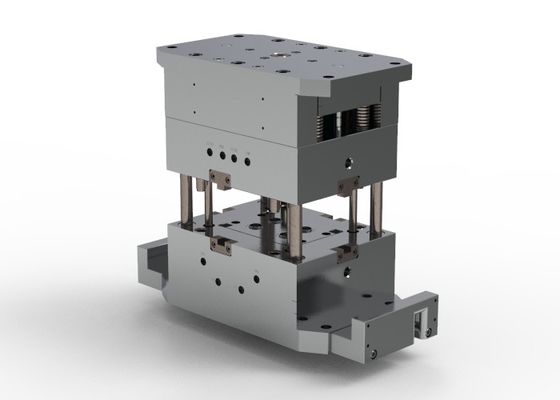

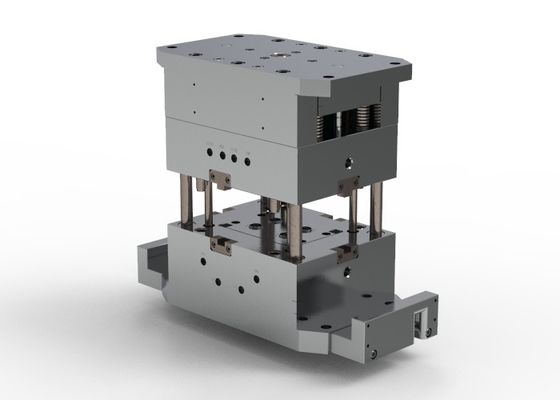

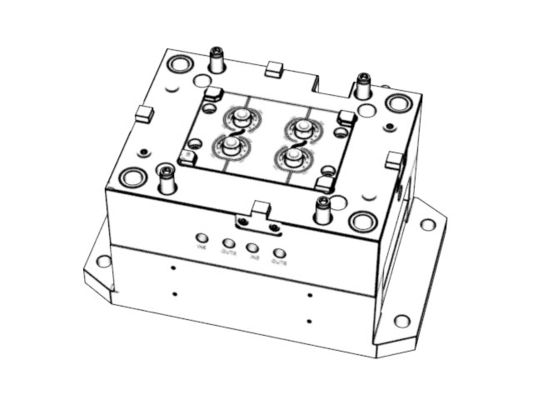

x| Size | 230 X 390 X 336 | IMM Tonnage | 120T |

|---|---|---|---|

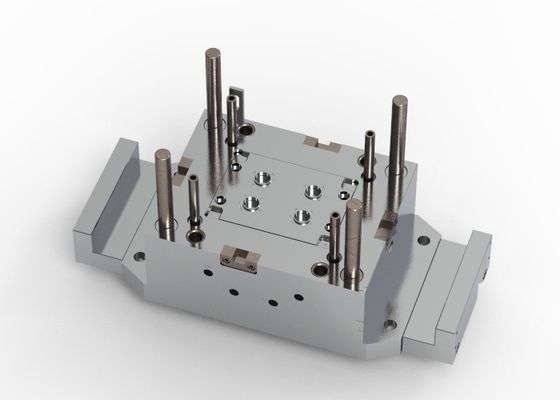

| Feature | 2 Shots Molding | Custom Mold Base P/N | FCI2330.609080. |

| Injection/runner Type | Hot Runner | Gate | Side Gate+pin Point Gate (hot Runner Turns To Cold Runner) |

| Part Material | PC/TPU | Type | Two-plates Mold |

| Design Software | 3D-UG 4.0/ 2D-CAD |

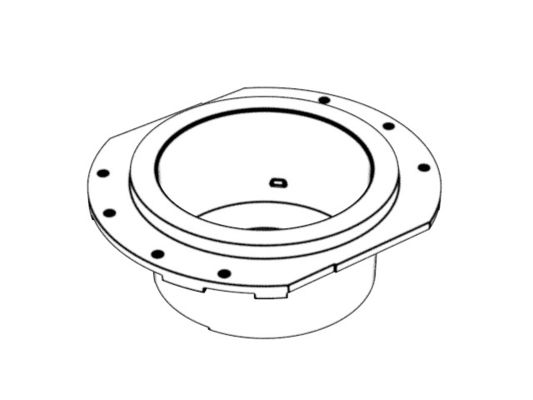

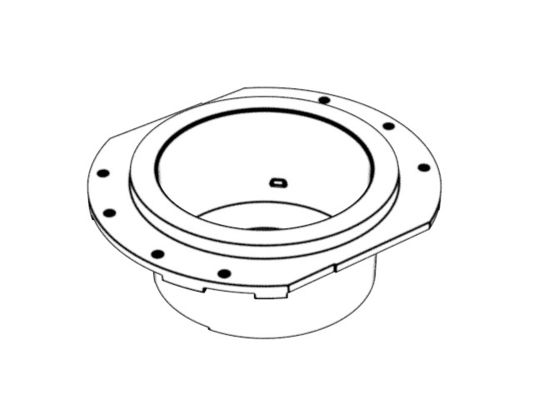

Smart Doorbell Button (1*4)

No.23675 & 23676-B

Description:

| Double Injection Molding, also known as two-shot molding, is a highly advanced manufacturing process employed by our company to manufacture top-quality plastic parts. This technique involves injecting two distinct materials into a single mold, resulting in a finished product that exhibits two different colors or materials. One of the primary advantages of Double Injection Molding lies in its capability to create intricate and complex designs. By combining two materials with varying properties, we can achieve improved functionality and aesthetics in the final product. Additionally, this process eliminates the need for secondary assembly or bonding, thereby reducing both production time and costs. Another notable benefit of Double Injection Molding is the enhanced strength and durability of the parts produced. The utilization of two materials with complementary properties, such as a rigid material for structural support and a soft material for cushioning or grip, significantly enhances the overall performance and longevity of the product. Moreover, Double Injection Molding offers exceptional design flexibility. It enables the creation of multi-material components with diverse textures, finishes, and colors. This versatility opens up a wide array of possibilities for product customization and differentiation. In summary, Double Injection Molding is a sophisticated manufacturing technique that enables the production of complex, durable, and aesthetically pleasing plastic parts. Its ability to combine different materials in a single mold offers enhanced functionality, design flexibility, and cost efficiency. |

Application:

Daily necessities

auto parts

medical accessories

Consumer electronics housing

decoration

Figure

Features:

| Custom mold base P/N | FCI2330.609080. |

| Mold Size | Length 230 * Width 390 * Height 336 |

| Type | Two-plates mold |

| Injection/runner type | Hot runner |

| Standard | LKM |

| Net weight | 145kg |

| Gate | Side gate + Pin point gate |

| Surface finish | A surface polished to SPI-A1 |

| Harden with S136 | Steel of cavity + Steel of core |

| Part material | PC/TPU |

| Part weight | One shot 0.5g & Two-shot 1.3g |

| Part size | Length 28.36 * Width 32.16 * Height 11.6 |

| IMM tonnage | 2k machine 120T |

|

This is a 2k mold with stable high quality and good molding. The mold is hardened to have high hardness, good strength and anti-wearing performance. The mold wall is smooth with uniform thickness. The tool life > 500k shots. The molded part has fine appearance, short cycle time, no loss of material, w/o leakage, greatly reducing the material and labor cost. |

|

Advantage:

| Our company specializes in the production and manufacturing of Double Injection Molding (DIM) molds, which provide numerous advantages in the manufacturing process. DIM is a sophisticated technique that enables the creation of intricate and multi-material products within a single molding cycle. This process involves injecting two distinct materials into a single mold, resulting in a finished product that exhibits enhanced functionality and aesthetics. Advantages of Double Injection Molding: Enhanced Design Flexibility: Double Injection Molding allows for the production of intricate designs and complex geometries that are challenging to achieve with traditional molding techniques. This capability enables the creation of products with unique shapes, textures, and patterns. Improved Product Quality: By combining two different materials, Double Injection Molding enhances the overall quality and performance of the final product. It facilitates the integration of diverse properties, such as hardness, flexibility, and color, into a single component, resulting in a more durable and visually appealing end product. Cost Efficiency: Double Injection Molding eliminates the need for secondary assembly processes, as multiple materials can be molded together in a single cycle. This reduction in production time and labor costs makes it a cost-effective solution for manufacturing complex parts. Waste Reduction: With Double Injection Molding, there is minimal material waste as the two materials are precisely injected into the mold. This not only reduces material costs but also contributes to a more sustainable manufacturing process. Versatility: Double Injection Molding finds applications in a wide range of industries, including automotive, electronics, consumer goods, and medical devices. It offers versatility in terms of material selection, allowing for the combination of different materials with varying properties to meet specific product requirements. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()