OEM / ODM : Polypropylene Injection Molding & Router Light Guide Plate (1*4) o.23893-B

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

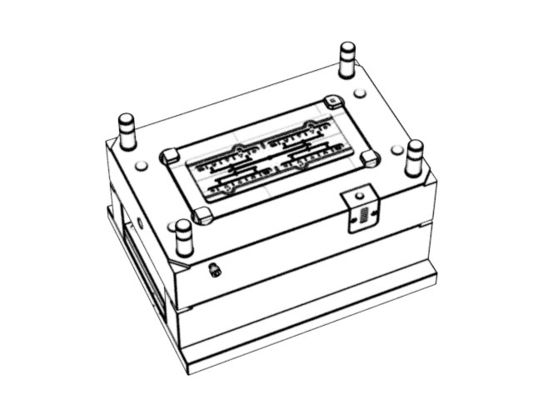

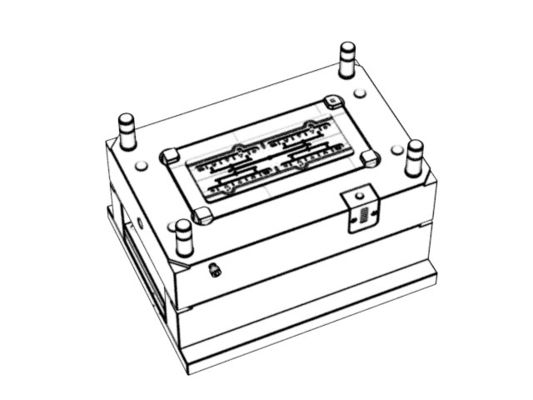

x| Size | [L] 280 X [W] 350 X [H] 271 | Service Life | Up To 50w Shots/time |

|---|---|---|---|

| IMM Tonnage | 80T | Mold Weight | 159kg |

| Gate | Side Gate | Part Material | PC |

| Standard | LKM |

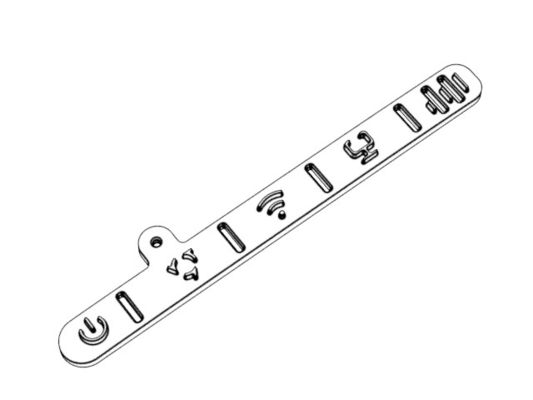

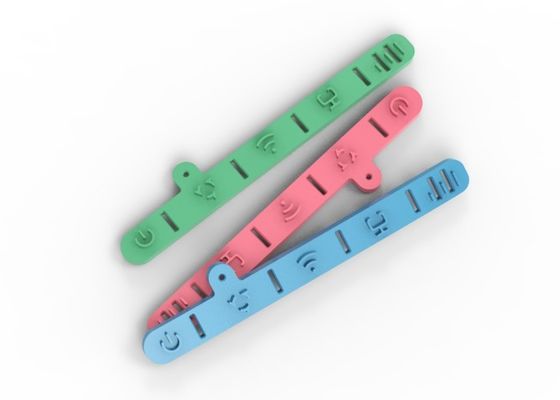

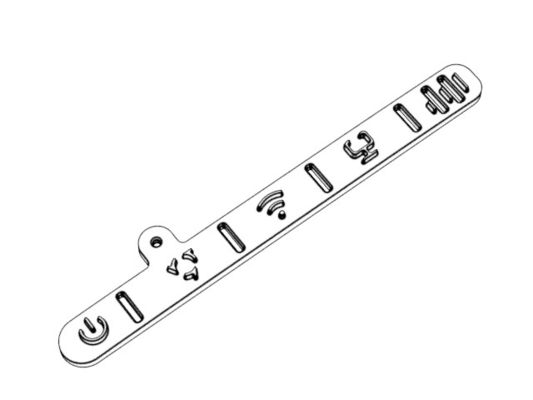

Router Light Guide Plate (1*4)

No.23893-B

Description:

| Our company specializes in the production of polypropylene injection molding, a process that involves the use of advanced machinery and techniques to create high-quality plastic components. Polypropylene, a versatile thermoplastic polymer, is carefully processed using state-of-the-art injection molding equipment under precise conditions to ensure the production of durable, dimensionally accurate parts. Our team of skilled technicians and engineers oversees the entire manufacturing process, from material selection to final inspection, to guarantee that the finished products meet the highest industry standards. The polypropylene injection molding services we offer are tailored to meet the specific needs of our clients, providing them with reliable, cost-effective solutions for their plastic component requirements. |

Application:

button

router

Precision accessories

Precision plastic products

Features:

| Mold base P/N | CI2335 608080 |

| Size | [L] 280 x [W] 350 x [H] 271 mm |

| Net weight | 159kg |

| Standard | LKM |

| IMM Tonnage | 80T |

| Gate |

Side gate (with simple gate section, easy to cut and get precision dimension, with good and smooth surface for melt easy flow through) |

| Injection/runner type | Cold runner |

| Type | Two-plates mold |

|

This is a 2 plates mold, with simple structure, easy to build and maintain, good for PC material filling, robust and long tool life, with short cycle time and low tool cost. |

|

| Part material | PC |

| Part weight | 2.03g |

| Part weight/size | 14.05 X 84.40 X 6.50mm |

| Surface Finish | A surface EDM with Charmilles VDI3400-18# |

| Steel of cavity & core | Harden (1*4/S136) |

| Tool life | 500k shots |

Advantage:

| Our company's polypropylene injection molding process offers several distinct advantages. Firstly, our expertise in material selection and mold design allows us to create molds that are tailored to the specific characteristics of polypropylene, ensuring optimal performance and durability. Additionally, our state-of-the-art injection molding equipment and advanced processing techniques enable us to produce intricate and complex polypropylene components with exceptional precision and consistency. Furthermore, our rigorous quality control measures and thorough testing procedures ensure that each molded product meets the highest industry standards for strength, resilience, and dimensional accuracy. The polypropylene injection molding services we provide are characterized by their reliability, cost-effectiveness, and ability to meet the diverse needs of our clients. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()