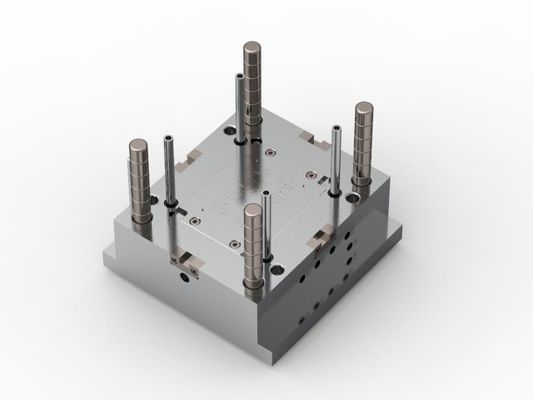

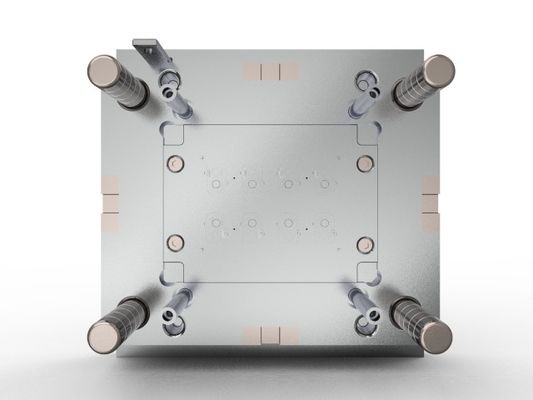

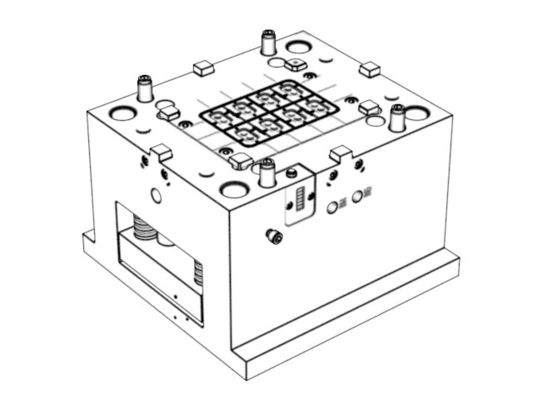

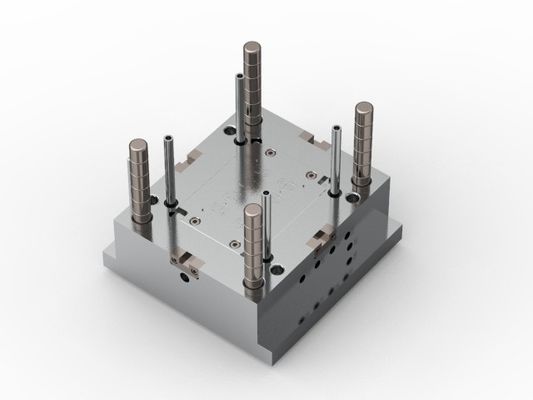

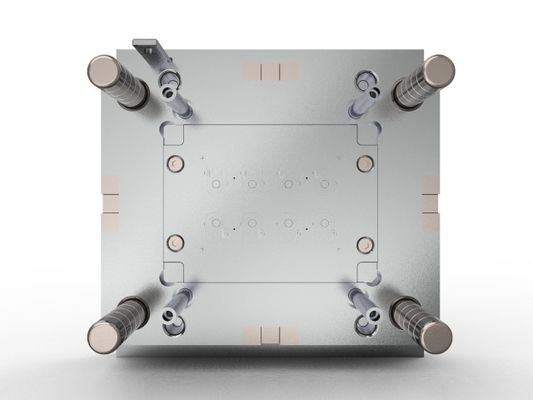

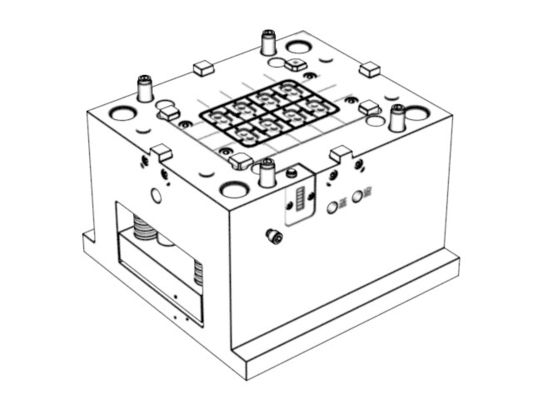

OEM / ODM : Precision Injection Molding & Scanner Camera Trim Ring (1*4) No.24005

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Mobile Phone |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Size | 400.000 X 450.000 X 421.000 | IMM Tonnage | 110T |

|---|---|---|---|

| Mold Weight | 254kg |

NScanner Camera Trim Ring (1*4)

No.24005

Description:

Precision Injection Molding is a highly advanced manufacturing process that utilizes computer-controlled machinery to produce intricate and complex plastic components with exceptional accuracy and repeatability. This process involves the injection of molten plastic material into a precisely designed mold cavity, which is then cooled and solidified to form the desired part. The key to the success of precision injection molding lies in the precise control of various parameters such as temperature, pressure, and cooling rate, as well as the use of high-quality molds and advanced materials. This results in the production of components with tight tolerances, excellent surface finish, and superior mechanical properties, making it an ideal manufacturing solution for industries such as automotive, medical, aerospace, and consumer electronics.

Advantage:

Our company's Precision Injection Molding molds offer several distinct advantages in the manufacturing process. Firstly, our molds are meticulously designed and engineered using advanced CAD/CAM software and cutting-edge machining techniques, ensuring the highest level of precision and consistency in the produced parts. Secondly, we utilize high-quality tool steels and advanced surface treatments to enhance the durability and longevity of our molds, resulting in extended production runs and reduced maintenance downtime. Additionally, our molds are equipped with innovative features such as conformal cooling channels and advanced venting systems, optimizing the molding process and minimizing cycle times. Furthermore, our expertise in mold design allows for the efficient production of complex geometries and tight tolerances, meeting the stringent requirements of various industries. Overall, our Precision Injection Molding molds stand out for their precision, durability, and efficiency, making them the preferred choice for demanding manufacturing applications.

| [Mold size] | [Mold base P/N] | ||||

| Length | Width | Height | FCI3035 609080 | ||

| 350 | 350 | 331 | |||

| [Standard]: LKM | [Type]: Three-plates mold | [Gate]: Pin point gate | |||

| [Mold net weight]: - 254kg |

[Steel of cavity & core]: - Harden (1*1/S136) |

||||

| [IMM Tonnage]: - 110T |

[Part material]: - PC |

||||

| [Part weight]: - 8.3g |

[Part size]: - 53.62X8.09X101.85mm |

||||

| Injection/runner type: Cold runner | |||||

| [Surface finish]: - A surface EDM with VDI27# |

[Features]: - 4 x slides and 1 x lifter |

||||

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()

....bart