Wear Resistant Transparent Earphone Terminal (1*8) No.23570-C

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| IMM Tonnage | 60 (T) | Mold Weight | 27.54(kg) |

|---|---|---|---|

| Gate | Sub Gate | Type | Two-plates Mold |

| Slide | 2 | Cavity/Core | Harden With 1*8/S136 |

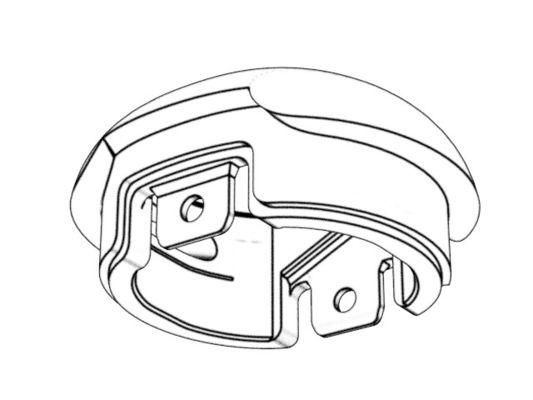

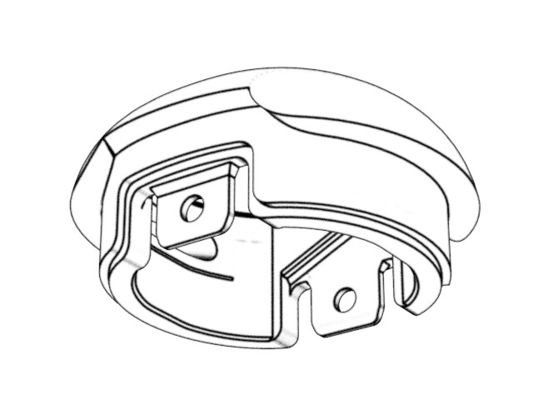

| Part Size | 6.21 X 5.61 X 2.91mm | Part Weight | 0.03g |

| High Light | OEM Transparent Earphone Terminal,Two Plate Transparent Earphone Terminal,Wear Resistant Earphone Terminal |

||

Transparent Earphone terminal (1*8)

No.23570-C

Description:

|

Our company specializes in the production of Precision Injection Molding, a manufacturing process that involves injecting molten material into a mold cavity under high pressure. This process allows for the creation of complex and intricate parts with high precision and accuracy. The key characteristics of Precision Injection Molding include achieving tight tolerances, versatility in producing a wide range of products, cost-effectiveness, consistency in quality, and the ability to work with various materials. |

Application:

Our Precision Injection Molding services are ideal for electronic products, precision electronics,

consumer electronics products, tablet products, and drones.

Features:

|

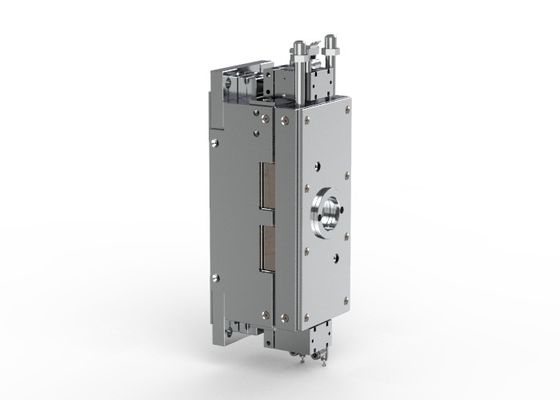

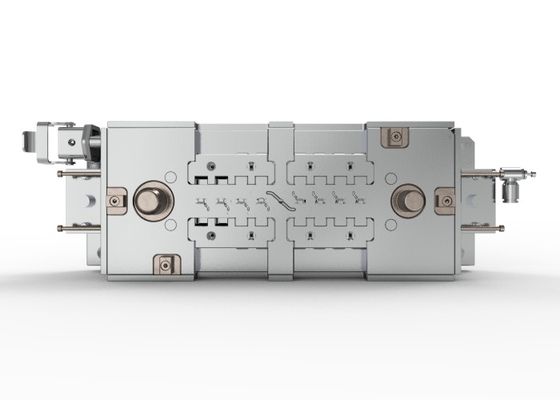

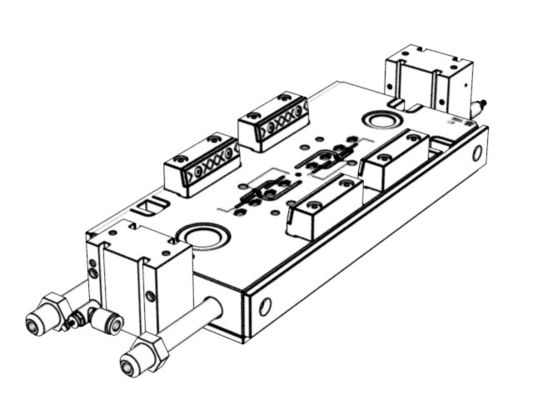

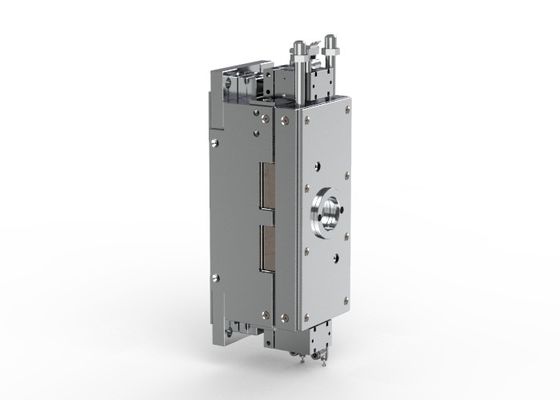

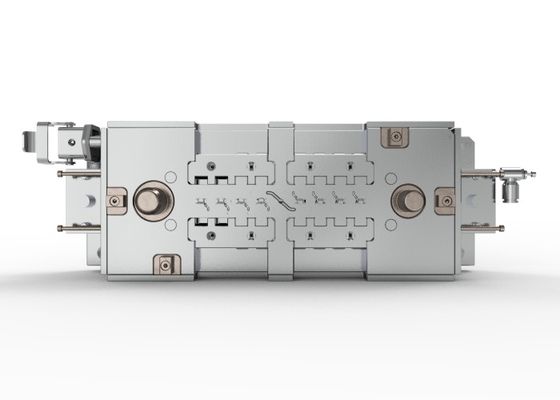

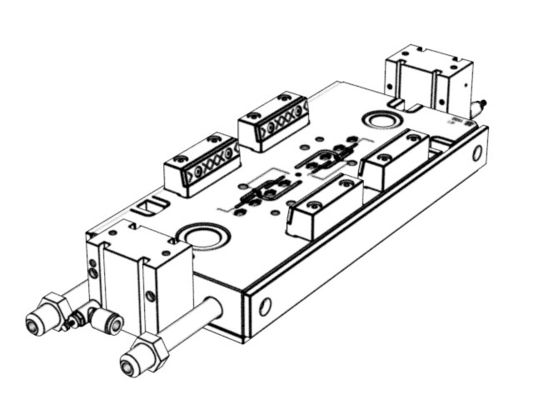

Type: Two-plate mold

The two-plate mold, manufactured according to LKM standards, is designed with a size of 110x330x125. It features two slides and has a net weight of 27.54kg. The mold is suitable for an injection molding machine with a tonnage of 60T. The gate used is a sub gate, and the part material is PA.

To ensure durability and performance, the cavity and core of the mold are hardened with 1*8/S136, providing higher hardness and resistance to wear and corrosion. The part size is 6.21 X 5.61 X 2.91mm, with a weight of 0.03g.

This two-plate mold is equipped with a cold runner system, which eliminates the need for manual labor and reduces the time and cost associated with early research and development and design. The mold's surface is polished to SPI-A3 standard, ensuring a smooth finish. The uniform thickness of the mold's wall allows for precise molding of the molten PA material, resulting in molded parts with stable quality, no sink marks, and precise thread formation. |

Advantage:

| Our company excels in the production and fabrication of precision injection molding tools, offering numerous advantages within the industry. To begin with, our team of engineers and technicians are highly skilled professionals with extensive experience in designing and creating precision injection molds. Their expertise guarantees that we can fulfill the exact specifications and tolerances needed for precision injection molding. Moreover, we utilize cutting-edge technology and modern equipment in our manufacturing procedures. This allows us to achieve remarkable levels of precision and accuracy in the production of injection molds, resulting in top-notch quality and performance. In addition, we place a strong emphasis on quality control at every step of the manufacturing process. Our strict quality assurance measures ensure that each mold undergoes thorough inspection and testing before being delivered to our clients. This dedication to quality ensures that our customers receive molds that meet their specific requirements and deliver outstanding results. Furthermore, we are committed to offering exceptional customer support and post-sales service. Our team is always available to address any questions or concerns that our clients may have, fostering lasting relationships built on trust and satisfaction. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()

![]()

![]()