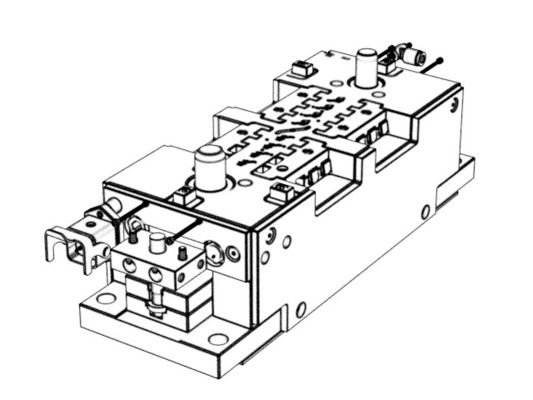

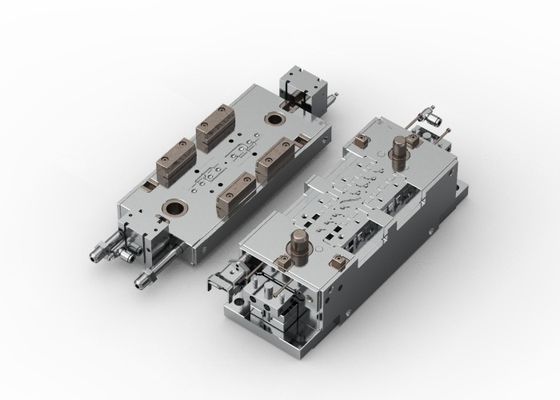

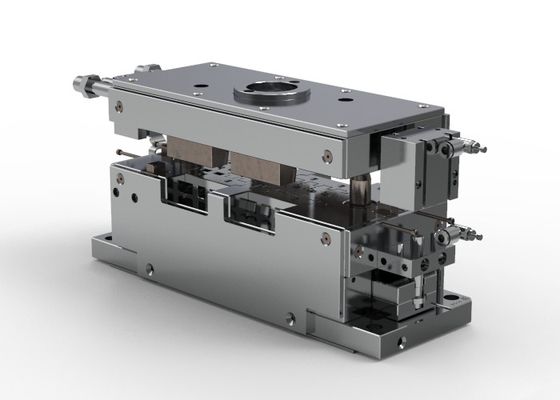

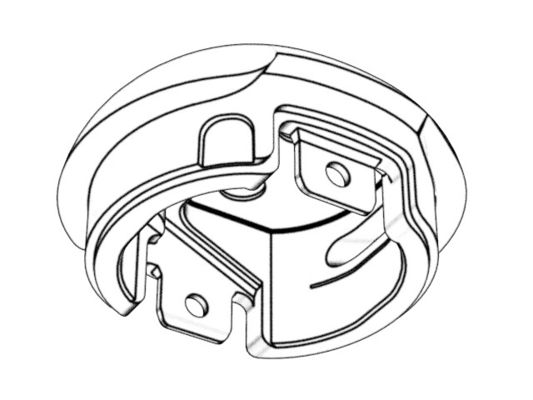

OEM / ODM Earphone Terminal (1*8) No.23570-C Precision Injection Molding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

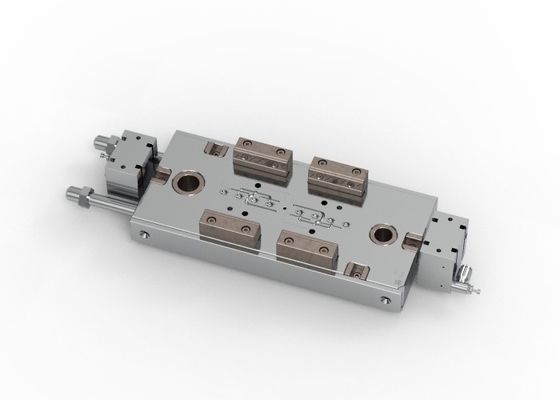

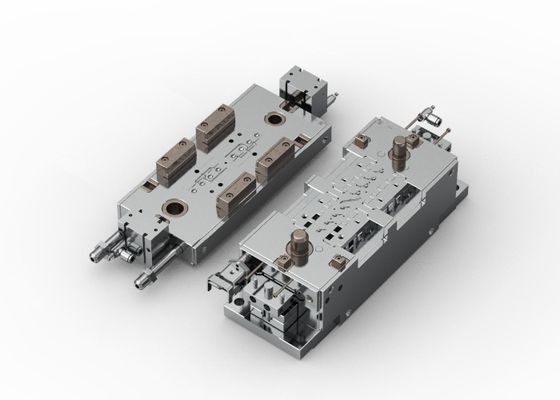

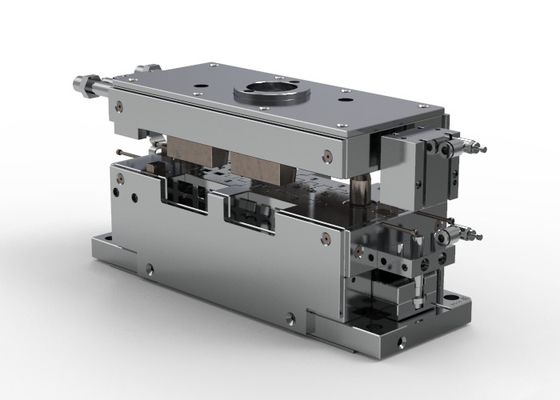

x| Size | 110.000 X 330.000 X 125.000 | IMM Tonnage | 60T |

|---|---|---|---|

| Mold Weight | 27.54kg | Standard | LKM |

| Type | Two-plates Mold | Slide | 2 |

| Part Material | PA | Gate | Sub Gate |

| Design Software | <3D:UG 4.0>/ <2D:CAD> | ||

| High Light | Earphone Terminal Precision Injection Molding,ODM Earphone Terminal Injection Molding |

||

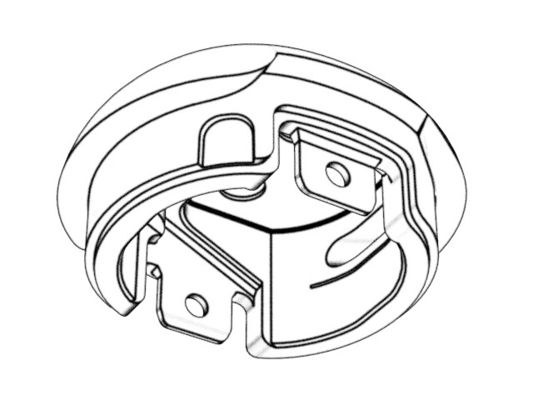

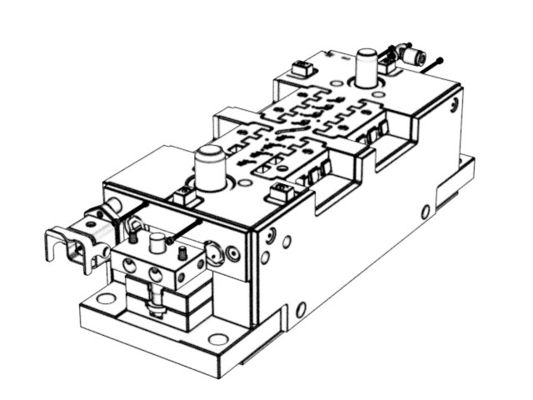

Earphone terminal (1*8)

No.23570-C

Description:

|

Our company specializes in the field of Precision Injection Molding, which is a highly precise and versatile manufacturing process. By injecting molten material into a mold cavity under high pressure, we have the capability to create intricate and complex parts with exceptional precision and accuracy. Precision Injection Molding offers a multitude of key characteristics. Firstly, it allows us to achieve tight tolerances and produce parts with intricate details, ensuring that the final products meet precise specifications and requirements. Secondly, it provides versatility in manufacturing a wide range of products, from small and intricate components to larger parts, accommodating various shapes, sizes, and complexities. Furthermore, Precision Injection Molding is a cost-effective solution, offering advantages in material usage, production efficiency, and reduced labor costs. The process enables high-volume production, resulting in economies of scale and lower per-unit costs. Additionally, it guarantees consistent quality and uniformity in the produced parts, as the process is highly repeatable, minimizing variations and defects, and meeting the required standards. Lastly, Precision Injection Molding supports a diverse range of materials, including thermoplastics, elastomers, and engineering polymers. This provides the flexibility to select the most suitable material for each specific application, ensuring optimal performance and functionality. |

Application:

precision instrument

Consumer electronics products

mobile

Features:

|

Dimensions: 110 x 330 x 125mm Mold Type: Two-plates Manufacturer Standard: LKM Gate Type: Sub gate Weight of Mold: 27.54kg Number of Slides: 2 Cavity & Core Material: Hardened with 1*8/S136 Part Material/Weight: PA/0.03g Part Size: 6.21 x 5.61 x 2.91mm Injection Molding Machine Tonnage: 60T. |

| Considering the cost and feasibility aspects, we have developed a blueprint for a two-plate mold with a cold runner and two slides. This blueprint guarantees a scientifically proven and steady molding process, leading to impeccable fitting of the parts. To elevate the overall standard, we have utilized a surface polishing method that adheres to the SPI-A3 criteria. Furthermore, we have toughened the surface to enhance smoothness, hardness, resistance to wear and corrosion, and to prevent molten PA from sticking. Thanks to these strategies, the molded components boast a brief cycle time, minimal material wastage, a flawless and sophisticated look, all at an economical price without compromising on quality. |

Advantage:

|

Our company specializes in the production and manufacturing of precision injection molding tools, offering a range of unique benefits within the industry. Firstly, we take pride in our highly skilled team of engineers and technicians who possess extensive expertise in designing and fabricating precision injection molds. Their deep understanding of the complexities involved in mold creation ensures that we can meet the exact specifications and tolerances required for precision injection molding. Additionally, we harness advanced technology and state-of-the-art equipment throughout our manufacturing processes. This enables us to achieve unparalleled levels of precision and accuracy in the production of injection molds, resulting in superior quality and performance. Furthermore, we place a strong emphasis on quality control at every stage of the manufacturing process. Our rigorous quality assurance protocols guarantee that each mold undergoes thorough inspection and testing before it is delivered to our clients. This unwavering commitment to quality ensures that our customers receive molds that not only meet their precise requirements but also deliver optimal results. Moreover, we are dedicated to providing exceptional customer support and after-sales service. Our team is readily available to address any inquiries or concerns that our clients may have, fostering long-term relationships based on trust and satisfaction. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()