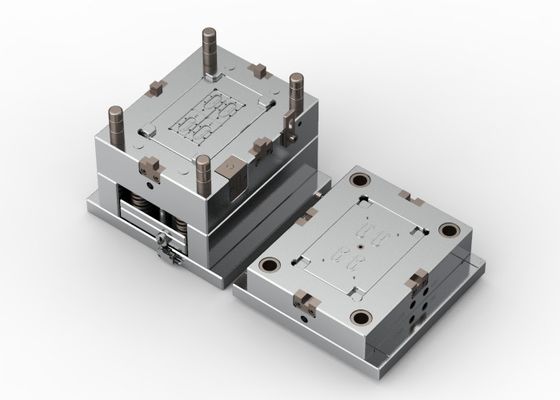

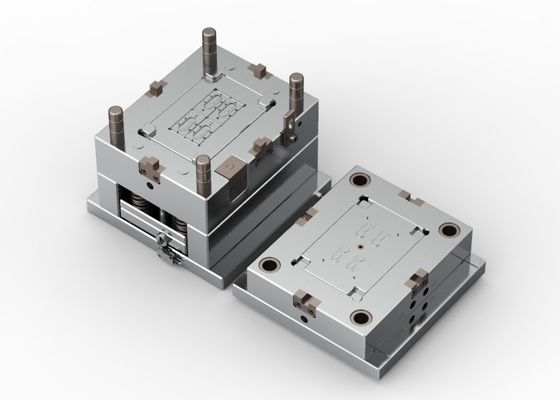

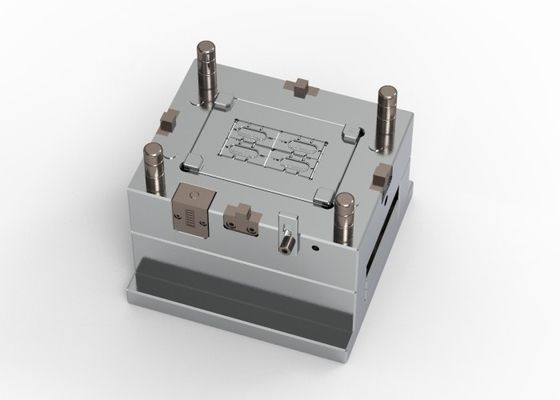

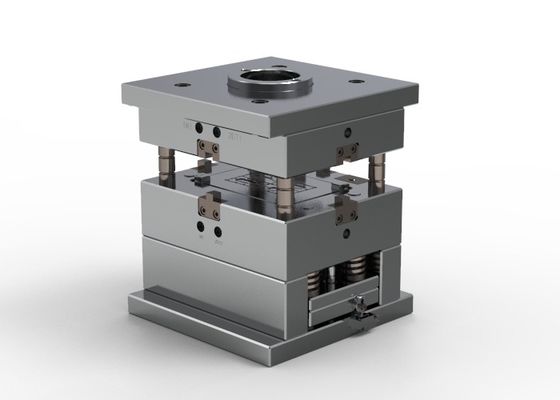

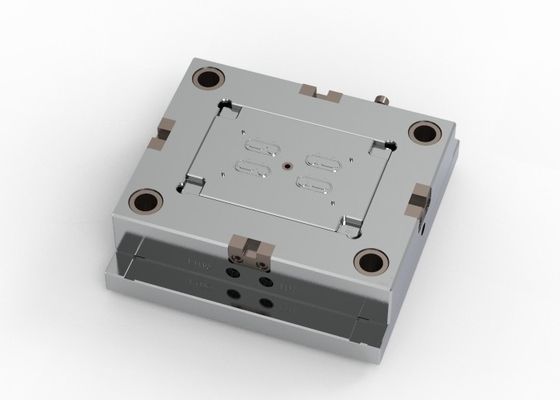

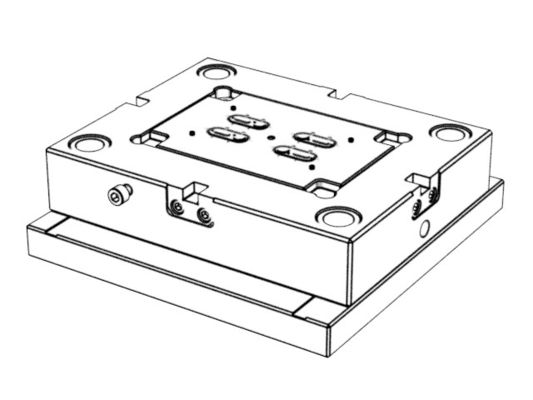

OEM / ODM Precision Injection Mold Transparent Scanning Pen Camera Decorative Ring (1*4) No.24005-D

| Place of Origin | China |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | Mobile Phone |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Size | 400.000 X 450.000 X 421.000 | IMM Tonnage | 110T |

|---|---|---|---|

| Mold Weight | 254kg | ||

| Highlight | Transparent Scanning Pen Precision Injection Mold,Decorative Ring Precision Injection Mold |

||

Transparent Scanning Pen Camera

Decorative Ring (1*4)

No.24005-D

Description:

| Our "Cold Runner Injection Molding" molds offer distinct advantages that differentiate them in the industry. Firstly, they are engineered to minimize material wastage, leading to cost savings and improved efficiency over time. Additionally, the cold runner system ensures better control over the molding process, resulting in consistently high-quality parts. This is especially advantageous for applications that require precision and reliability. Furthermore, the design of our cold runner molds allows for easy color changes and material transitions, providing flexibility to meet diverse production needs. Overall, our cold runner injection molding process delivers cost-effectiveness, precision, and versatility, making it a preferred choice for numerous manufacturing applications. |

Application:

Accessories for smart doorbells

Consumer Electronics

High-quality accessories

Accessories for mobile phones

Digital Accessories.

Features:

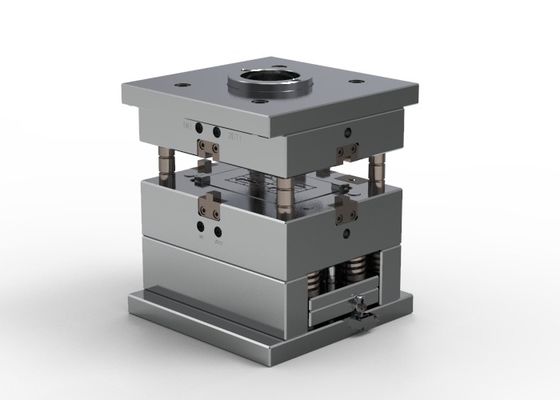

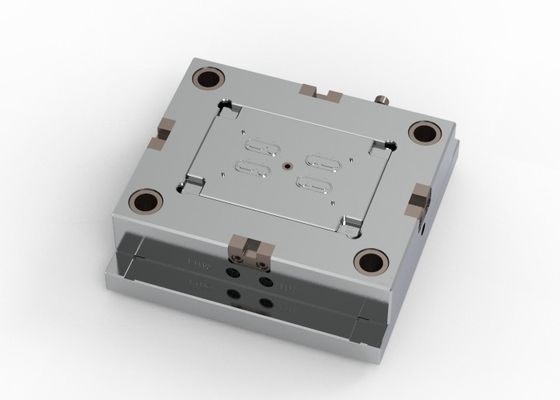

| Mold size | Length | 350 | Width | 350 | Height | 331 |

| Mold base P/N | FCI3035 609080 | |||||

| Standard | LKM | |||||

| Type | Three-plates mold | |||||

| Gate | Pin point gate | |||||

| Mold net weight | 254kg | |||||

| Steel of cavity & core | Harden (1*1/S136) | |||||

| IMM Tonnage | 110T | |||||

| Part material | PC | |||||

| Part weight | 8.3g | |||||

| Part size | 53.62X8.09X101.85mm | |||||

| Injection/runner type | Cold runner | |||||

| Surface finish | A surface EDM with VDI27# | |||||

| Features | 4 x slides and 1 x lifter | |||||

Advantage:

|

Our Cold Runner Injection Molding technology has been proven as a dependable and cost-efficient solution for numerous clients. By reducing material waste and promoting effective reusability, these molds help in saving costs and supporting environmental sustainability. The cold runner system's precise control guarantees consistent part quality, making it ideal for a broad spectrum of applications, especially those demanding high precision. Moreover, the adaptable design of the cold runner enables seamless color changes and material transitions, catering to a variety of production requirements. In summary, our Cold Runner Injection Molding process offers efficiency, accuracy, and versatility, establishing itself as a top choice for different industrial needs. |

![]()

![]()

![]()

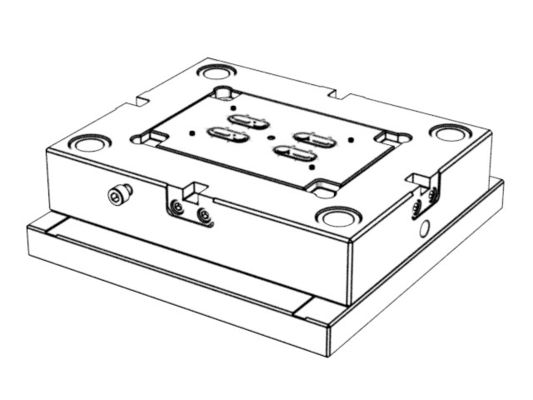

Display diagram

![]()

![]()

![]()

![]()

...bart