OEM / ODM On-board Universal Joint Ball Head (1*4) No.24118-C

| Place of Origin | India |

|---|---|

| Brand Name | Chitwing |

| Certification | ISO 9001:2015 |

| Model Number | In-Car Products |

| Minimum Order Quantity | 1set |

| Price | Negotiable |

| Packaging Details | The mold is packaged with a wooden box and placed on a wood pallet. |

| Delivery Time | 30 day(s) |

| Payment Terms | L/C, T/T |

| Supply Ability | 200 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

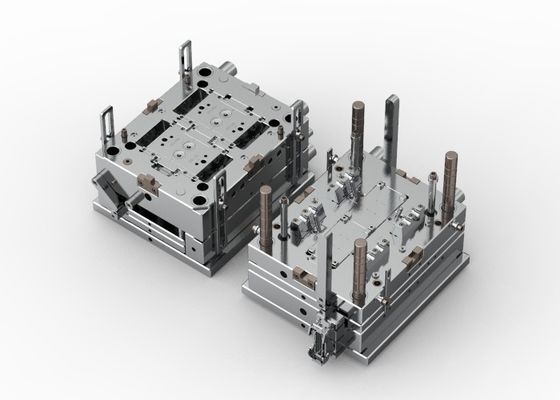

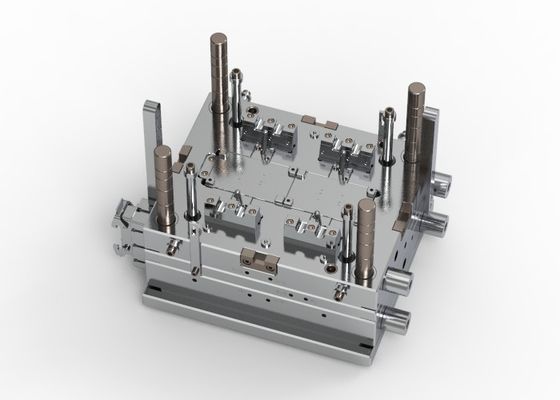

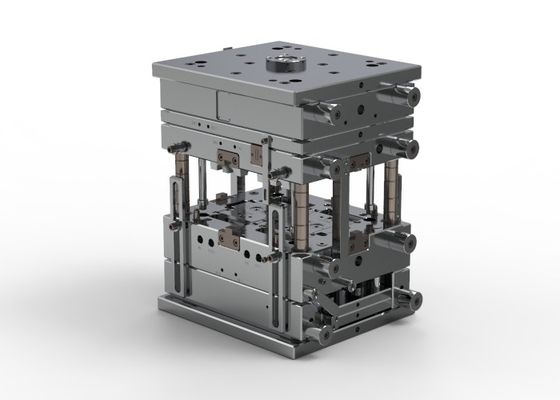

x| Size | 450.000 X 500.000 X 482 | IMM Tonnage | 220T |

|---|---|---|---|

| Mold Weight | 122kg | Standard | LKM |

| Type | Three-plates Mold | Steel Of Cavity & Core | Harden (1*4/S136) |

| Part Material | PC | Part Weight | 0.01g |

| High Light | On-board Universal Joint Ball Head,ODM Universal Joint Ball Head,OEM Universal Joint Ball Head |

||

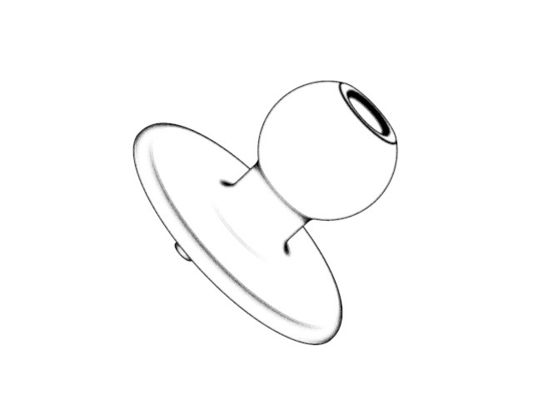

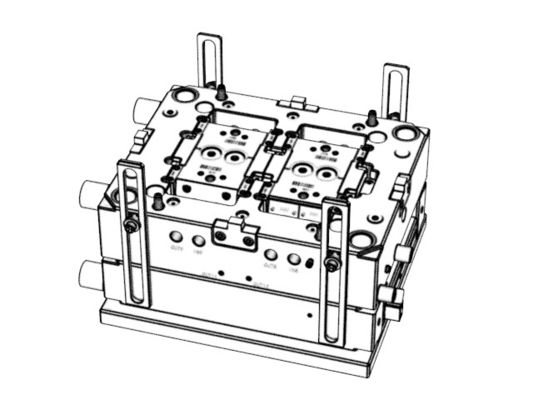

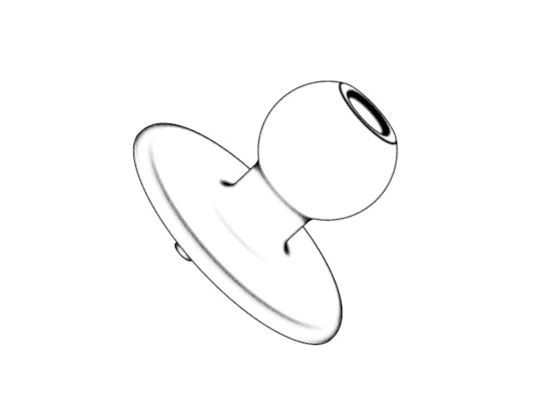

On-board Universal Joint Ball Head (1*4)

No.24118-C

Description:

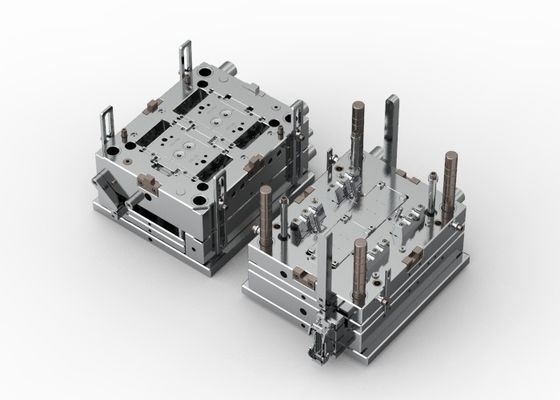

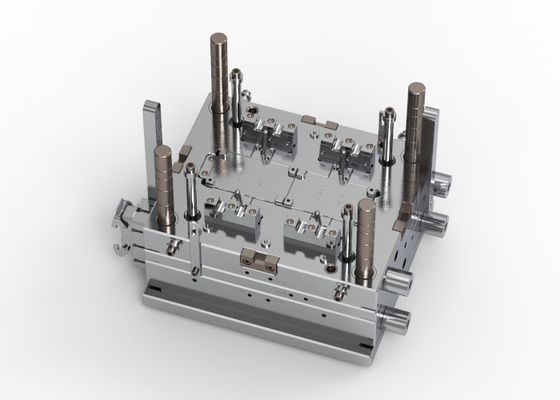

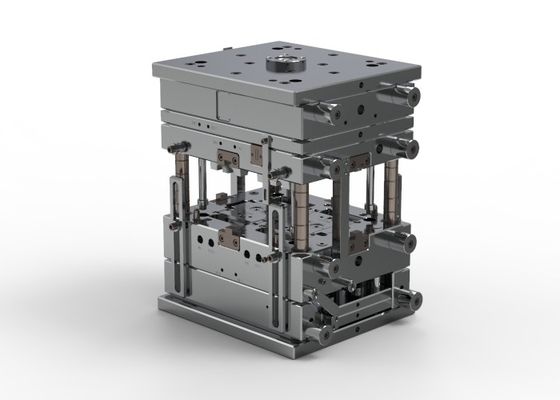

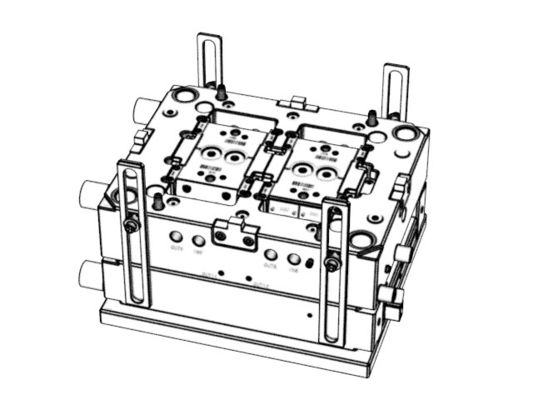

| Our company is dedicated to manufacturing Multi Cavity Injection Molds that are carefully crafted to enable the simultaneous production of multiple identical parts in a single molding cycle. These molds are engineered with great precision to guarantee consistent part quality and uniformity across all cavities, resulting in enhanced production efficiency and reduced cycle times. The sturdy construction of our Multi Cavity Injection Molds ensures long-lasting durability, contributing to cost-effectiveness and the ability to sustain high-volume manufacturing operations. Moreover, our molds can be customized to accommodate different part geometries and material specifications, offering versatility and adaptability to meet a wide range of production needs. |

Application:

Universal wheel accessories

Plastic connector

Injection molded components for everyday use

Everyday essentials

Features:

| Mold base P/N | FCI405070120100 | |

| Standard | LKM | |

| Type | Three-plates mold | |

| Mold size | Length | 450 |

| Width | 500 | |

| Height | 482 | |

| Gate | Pin point gate | |

| Injection/runner type | Hot runner | |

| Part material | PC | |

| Part weight | 0.01g | |

| Part size | 4.97 X 4.97 X 0.60mm | |

| Tool life | Up to 500K shots | |

| Mold net weight | 122kg | |

| IMM Tonnage | 220T | |

| Surface finish | Inner surface treated with SPI-B2 | |

| Steel of cavity & core | Harden (1*4/S136) | |

Advantage:

| Our Multi Cavity Injection Molds are engineered to transform the manufacturing process. By allowing for the simultaneous production of numerous identical parts in a single molding cycle, these molds significantly boost production efficiency and decrease lead times. The precise design of our molds ensures consistent part quality across all cavities, resulting in top-notch finished products. Furthermore, the durable construction of our Multi Cavity Injection Molds ensures longevity and reliability, resulting in cost savings and sustained high-volume manufacturing capabilities. Additionally, the customizable features of our molds enable the accommodation of various part geometries and material specifications, offering flexibility to meet a diverse array of production requirements. |

![]()

![]()

![]()

Display diagram

![]()

![]()

![]()

![]()

| Mold base P/N: FCI405070120100 | |||||

| Length | 450 | Standard | Type | ||

| Width | 500 | LKM | Three-plates mold | ||

| Height | 482 |

||||